- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Hydraulic Press Brake

Worktable Length: 2000mm ~ 6000mm

Open Height: 335mm ~ 545mm

Throat Depth: 200mm ~ 400mm

-

Structure of Hydraulic Press Brakes:

1)The all-steel-structure of SMC Press Brakes consist of side frames, ram, I-Beam and pair of levers manufactured from ultrasonically tested steel plates.

2)All sections are designed to give minimum deflections to maximum rigidity as per international standards.

3)Pair of hydraulic cylinders are synchronized by a heavy duty torque tube welded to the levers. This offers absolute parallelism between them and table working surfaces.

-

Special Machine Modifications and Customizations:

SMC has dedicated team of engineers to provide cost-effective solutions for your special forming requirements. In many cases, they work directly with clients to offer custom design for special bending and forming needs. From utilization of numerous standard options to complete custom modifications of ram open heights, bed cap dimensions, throat depths and much more, SMC can accommodate your special application needs.

-

Benefits of Hydraulic Press Brakes:

1)Low tooling cost

2)Easy & Quick setting

3)Enormous versatility

4)Accurate repetition & bending

5)User friendlyEasy maintenance

6)Standard spares, hence easy availability

-

Performances of Hydraulic Press Brakes:

1) All steel welded construction- high strength and good rigidity.

2) Hydraulic top drive–steadiness and reliability.

3) Mechanical leveling- torsion bar keeps synchronous operation and high precision.

4) Mechanization – adjust device of back gauge and ram stroke by operator hand rail.

5) Transit protection- whole machine guarding with safety interlocker.

6) Deflection compensator built into bed top.

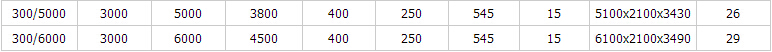

Specification of Hydraulic Press Brakes:

here

for

price