- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Advantages of Plastic Formworks in Concrete Construction

Plastic formworks for construction is to keep fresh concrete in position to gain strength. With the help of formworks, concrete is easily made into various shapes and size. And the structure constructs.

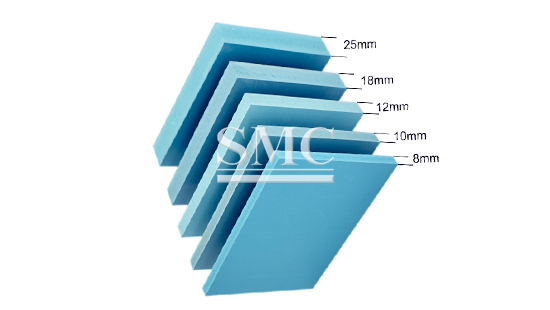

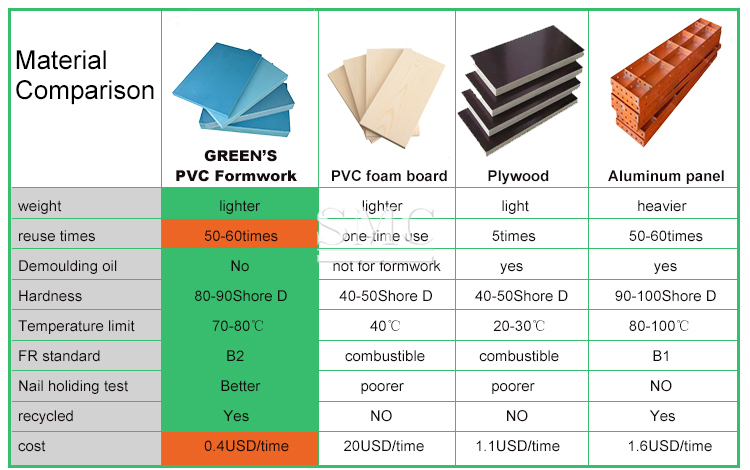

There is different material uses to make formworks. Mainly timber and steel. Plastic gives a number of advantage compares to other materials. some are durability, cost-effectiveness, and flexibility.

Plastic formworks

Advantages of Plastic Formworks in Concrete Construction

Plastic formworks have many advantages like durability, cost, and flexibility. Formworks expend large labor force and total cost of the project. Efforts have made to introduce a formwork system which is cost-effective. And assembles, dismantle and handle easily by labor.

Plastic formworks is the most labor-friendly system. It fits and plugs easily and considerably lightweight compares with other types of formwork systems.

4. Nailing and oiling

Plastic formworks

Other formworks cost high makes it not suitable to use. Plastic forms are recyclable. And it is eco-friendly. It reduces handling time. And provides great reusability index.