- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Diamond Embossed PPGI For Construction Decoration

Thickness: 0.12mm - 1.0mm

Width: ≤1250mm

Zinc Coating: Z40 - Z150

1) Thickness: 0.15mm - 0.9mm

2) Width: 600mm - 1250mm

3) Top coating: 17µm - 25µm

4) Back coating: 6µm - 10µm

5) Based steel: galvanized steel coil/galvalume steel coil

6) Coil weight: 3 - 5 tons

7) Coil ID: 508mm, 610mm

8) Color: All RAL color or as clients' Sample

Advantages of Diamond Embossed PPGI:

1) Environmental and economic2) PPGI steel coil do less harm to environment and can be used many time

3) PPGI steel coil is very light can save transport cost; convenient to corrugated and fixed

4) It can be corrugated to difference shapes and fixed conveniently

Remark: 20ft container can max stand 25 tons, each coil 3-5 tons, one container can take 25-27 tons

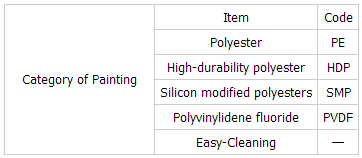

Painting Catagory:

Technical Parameters:

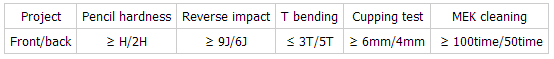

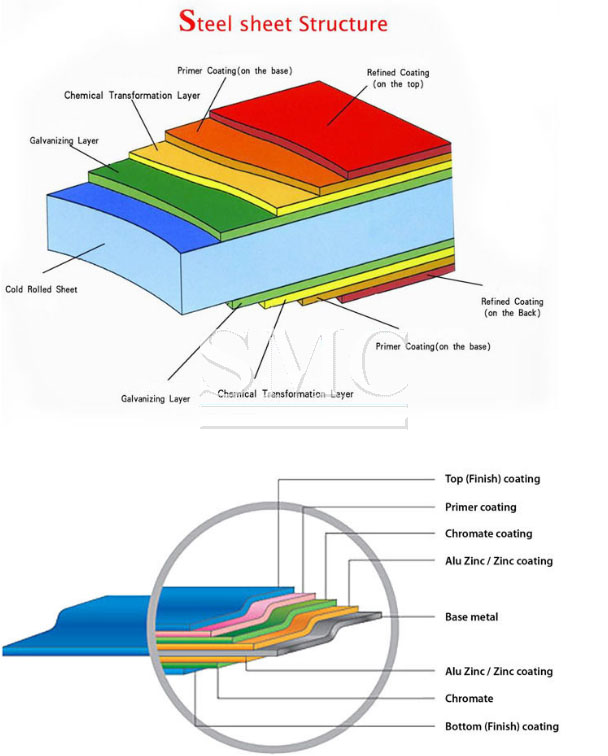

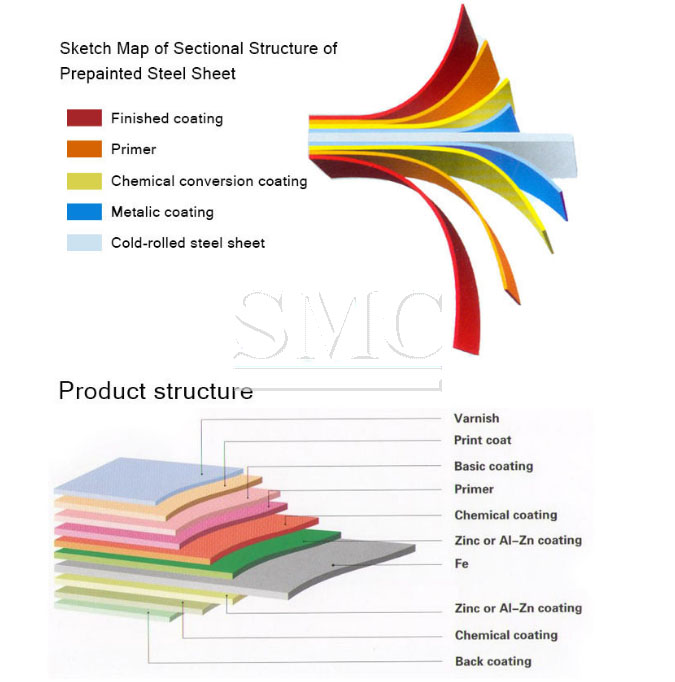

Structure of Diamond Embossed PPGI:

1) Topcoat (finishing) which provides color, pleasing appearance and appearance and a barrier film to enhance long-term durability

2) Primer coat to prevent undercutting of paint and enhance corrosion resistance

3) Pretreatment layer applied for good adhesion and to enhance corrosion resistance

4) Base steel sheet

Production Facility of Diamond Embossed PPGI:

Pay-off Section

The operating principles and functions are similar to the galvanizing process, except that it uses a joiner to fasten the steel sheets together.

Clean, Pre-treatment and Chemical Coating

The GI coil is cleaned at the degreaser tank, where oil and dust are removed by chemical means. The white rust formed on the surface can be removed at the brush assembly. The clean coil will then be coated with conditioner and chromate at the conditioner and chromate tank respectively, to provide better adhesion and corrosion resistance ability.

Prime and Finish Coating

A basic layer of paint, called primer, is applied on the chemical coater in order to strengthen the corrosion resistance and paint adhesion ability. The requested colours and specifications of paint will be applied at both the top and bottom of the primer coated coil to complete the painting work.

Prime and Finish Oven

The primer coating is further cured at the primer oven and cooled at the primer water quench to ensure the painted coil is completely cured. Similarly, the finish oven and finish water quench also serve to ensure that the paint applied is completely cured and cooled.

Manufacturing of Diamond Embossed PPGI

Pay off reel → Double cut shear → Welder-notcher → Entry accumulator → Pre-cleaning section → Furnace → Hot bridle → Zinc pot → Air knife → After cooler → Water quench → Dryer → Skin pass mill → Dryer → Tension leveler → Dryer → Chemical coater → Chemical oven → Cooler → Exit accumulator → Oiler → Exit shear → Tension reel

Shanghai Metal Corporation is an international manufacturer and supplier for Prepainted Galvanized Steel Coil. We have two prepainted lines based on galvanized steel coil. Our monthly output for each line is approximately 5,000 ton.

Packaging of Diamond Embossed PPGI

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Diamond Embossed PPGI:

1) Contruction and building: roofing, ventilating duct, handrail, partition panel, etc.

2) Electric appliance: refrigerator; washing machine, microwave, DVD, etc.

3) Transportation: oil tank, road sign, etc.

4) Agriculture: barn, etc.

5) Others: vending machine, game machine, etc.

here

for

price