- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

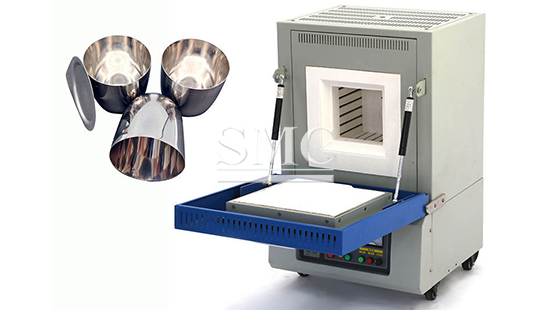

Platinum Crucible

Platinum crucibles are made from platinum with a purity exceeding 99% through a specialized process. They have a high melting point (1772°C), higher than that of gold, and are chemically stable, non-hygroscopic, and non-corrosive to most chemical reagents. They are commonly used in laboratory silicate rock chemical analysis for silica.

Platinum Crucible Processing:

1. Die Stamping

Disadvantages: Using a bottom die to stretch the platinum sheet, the force is applied locally, resulting in thinner walls in the stressed areas than in other areas. This can lead to uneven thicknesses throughout the crucible, ultimately impacting the lifespan of the crucible.

2. Spinning

Spinning involves mechanically rotating the sheet material, shifting the stress points from point to line to surface, while simultaneously applying pressure in a specific direction to deform and flow the metal material.

The spinning process overcomes the drawback of die stamping, where only localized force is applied to a specific point. Instead, the entire metal surface is evenly stressed, resulting in products with uniform wall thickness, high machining precision, and significantly improved service life compared to traditional die stamping processes.

Features of Spinning Products:

1. Smooth Surface

2. Uniform Wall Thickness

3. Single-Step Forming of Sheet Metal, No Seams or Welds

4. High Product Precision

Usage Precautions

1. The melting point of a platinum crucible is 1773.5°C. The operating temperature should not exceed 1200°C. Do not heat directly over an open flame.

2. When handling the crucible, avoid excessive force to prevent deformation or dents. Never use the tip of a glass rod to remove the contents.

3. Do not heat or melt alkali metal oxides, hydroxides, barium oxide, sodium thiosulfate, or substances containing phosphorus or high amounts of sulfur in a platinum crucible. Alkali metal nitrates, nitrites, oxides, chlorides, and cyanides react with platinum at high temperatures to form brittle platinum phosphide and platinum sulfide, which can corrode platinum.

4. Samples and compounds containing heavy metals such as lead, bismuth, tin, arsenic, silver, mercury, and copper should not be burned or heated in a platinum crucible.

5. During high-temperature heating, samples should not come into contact with any other metals (such as iron plates and electric furnaces). Be careful not to touch the electric corners when placing the sample in a high-temperature furnace.

6. Halogens such as aqua regia, bromine water, hydrochloric acid, and oxidizing agents (chlorates, nitrates, permanganates, manganese dioxide, chromates, and nitrites) should not be handled in a platinum crucible. Ferric chloride significantly corrodes platinum and should therefore not be allowed to come into contact with it.

7. Do not heat or dissolve substances of unknown composition in a platinum crucible.

8. The platinum crucible must be kept clean and shiny inside and out. After prolonged burning, the surface of the platinum crucible may become dull and matte. Over time, this can penetrate deep into the crucible, causing it to become brittle and crack. Therefore, any impurities must be removed.

For more information, please visit: https://www.shanghaimetal.com/platinum_crucible-15954.htm

For our full list of products that we offer check out our website here. Be sure to join the conversation in our LinkedIn group, Facebook, Twitter.

Try also our WeChat by scanning the QR code below.

Fever L.//SMC Editor