- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

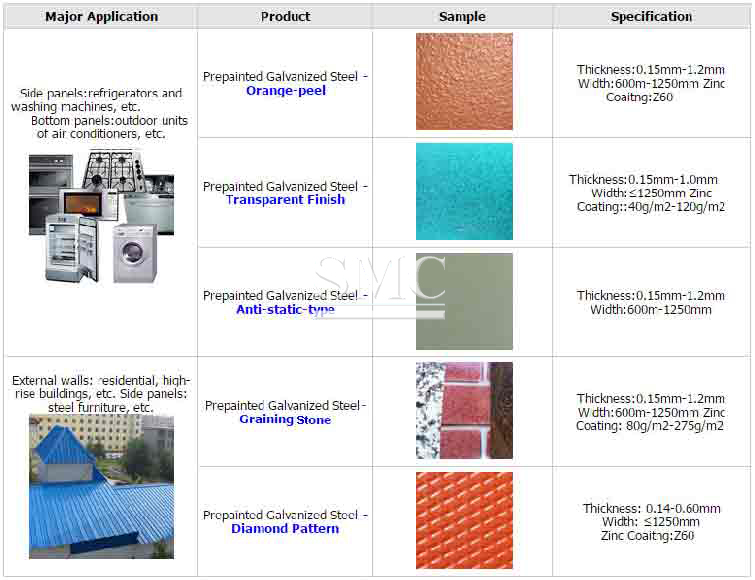

Prepainted Galvanized Steel Coil For Roof

Building materials: exterior & interior

Accessories: shutter, signboard

We offer different finishes of prepainted galvanized steel to satisfy all your needs. Let us know if you require a product or

service that you do not see listed here. We gladly to offer custom-manufactured sevice for your convenience.

Shanghai Metal produces the widest range of Prepainted Galvanized Steel Coil & Sheet, Pre-coated Metal

Sheet, laminated steel, pre-coated steel, and anti-fingerprint steel. PPGI is produced by coating two or more

layers paint applied on Cold-Rolled, Galvanized Steel, Electrolytic Galvanized Steel, base-steel, and then cut

into sheets. It is also called prepainted steel, pre-coated metal sheet.

Specifications of Prepainted Galvanized Steel Coil:

1) Capacity: over 10,000 ton per month for pre-painted galvanized steel

2) Standard: AISI, ASTM, BS, DIN, GB, JIS

3) Thickness: 0.13mm - 1.2mm, all available

4) Width: 600mm - 1250mm, all available

5) Length: according to the customer's request

6) Coil ID: 508/610mm

7) Coil weight: according to the customer's request

8) Coating Weight: AZ50 to AZ150

9) Spangle: regular spangle, small spangle, big spangle

10) Color: any RAL code

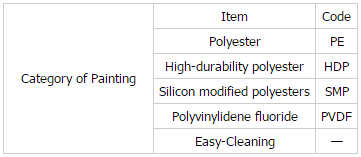

Painting Catagory:

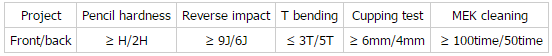

Technical Parameters:

Structure of Prepainted Galvanized Steel Coil:

1) Topcoat (finishing) which provides color, pleasing appearance and appearance and a barrier film to enhance long-term durability

2) Primer coat to prevent undercutting of paint and enhance corrosion resistance

3) Pretreatment layer applied for good adhesion and to enhance corrosion resistance

4) Base steel sheet

Production Facility of Prepainted Galvanized Steel Coil:

Pay-off Section

The operating principles and functions are similar to the galvanizing process, except that it uses a joiner to fasten the steel sheets together.

Clean, Pre-treatment and Chemical Coating

The GI coil is cleaned at the degreaser tank, where oil and dust are removed by chemical means. The white rust formed on the surface can be removed at the brush assembly. The clean coil will then be coated with conditioner and chromate at the conditioner and chromate tank respectively, to provide better adhesion and corrosion resistance ability.

Prime and Finish Coating

A basic layer of paint, called primer, is applied on the chemical coater in order to strengthen the corrosion resistance and paint adhesion ability. The requested colours and specifications of paint will be applied at both the top and bottom of the primer coated coil to complete the painting work.

Prime and Finish Oven

The primer coating is further cured at the primer oven and cooled at the primer water quench to ensure the painted coil is completely cured. Similarly, the finish oven and finish water quench also serve to ensure that the paint applied is completely cured and cooled.

Manufacturing of Prepainted Galvanized Steel Coil

Pay off reel → Double cut shear → Welder-notcher → Entry accumulator → Pre-cleaning section → Furnace → Hot bridle → Zinc pot → Air knife → After cooler → Water quench → Dryer → Skin pass mill → Dryer → Tension leveler → Dryer → Chemical coater → Chemical oven → Cooler → Exit accumulator → Oiler → Exit shear → Tension reel

Shanghai Metal Corporation is an international manufacturer and supplier for Prepainted Galvanized Steel Coil. We have two prepainted lines based on galvanized steel coil. Our monthly output for each line is approxiamtely 5,000 ton.

Packaging of Prepainted Galvanized Steel Coil

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Prepainted Galvanized Steel Coil:

1) Construction and building: roof, light steel roof structure, folding screen, elevator, stairway, vent gutter, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, drainage pipe, retailer booth, highway guardrails

2) Electric appliance: refrigerator, washing machine, microwave, DVD, etc.

3)Transportation: oil tank, road sign, etc.

4) Agriculture equipment: refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-ware oven, bread maker

5) Others: ventilation ducts, gutters and down spouts, Pre-paint and post paint applications, gutters and ceiling suspension bars, shutter door rails, electrical appliances, refrigerator appliances, signs, automotive parts, vending machines, washing machines, showcases and other structural use, roofing, commercial use, vending machine, game machine, etc.

here

for

price