- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

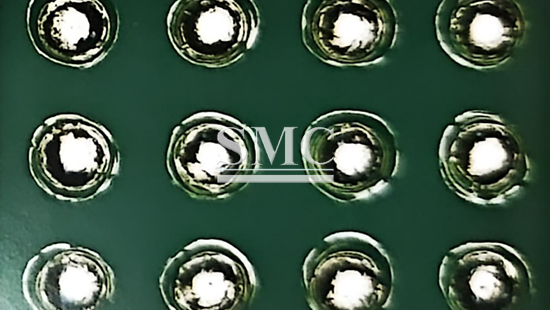

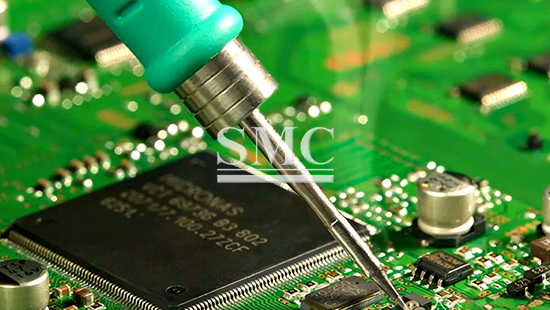

Solder Paste

Chemical Composition: Sn, Ag, Cu, Bi, Sb, Pb

Type: Lead / Lead-free / Tin-Bismuth Solder Paste

Tin Powder Particle Size: Type3, Type4, Type5, Type6

Shanghai Metal Corporation is a leading manufacturer and supplier of Solder Paste.

Solder paste is a new type of welding material developed alongside Surface Mount Technology (SMT). It is a paste-like mixture formed by blending solder powder, flux, and other additives such as surfactants and thixotropic agents. Primarily used in the SMT industry, it solders electronic components like resistors, capacitors, and ICs onto PCB pads. At room temperature, solder paste exhibits a certain tackiness, enabling the initial adhesion of components to their designated positions. At soldering temperatures, as the solvent and some additives volatilize, it permanently bonds the components to the printed circuit board pads.

We can supply solder pastes for different applications. You can find them in the “Technical Information” Column.

For more information about our mechanical products or to request a quotation for Solder Paste, please contact us. We will respond within 24 hours.

Technical Information of Solder Paste:

|

Commonly Used Alloys in Solder Paste and Their Melting Points |

|||||

|

Type |

Alloy Composition |

Melting Temperature(℃) |

Packaging Format |

||

|

|

|

Solidus |

Liquidus |

Jars |

Syringes |

|

Lead-free |

Sn96.5Ag3.0Cu0.5 |

217 |

221 |

√ |

√ |

|

|

Sn99.0Ag0.3Cu0.7 |

217 |

227 |

√ |

√ |

|

|

Sn98.5Ag1.0Cu0.5 |

217 |

227 |

√ |

√ |

|

|

Sn90Sb10 |

240 |

250 |

√ |

√ |

|

|

Sn95Sb5 |

235 |

240 |

√ |

√ |

|

Tin-Bismuth |

Sn42Bi58 |

138 |

138 |

√ |

√ |

|

|

Sn42Bi57Ag1 |

137 |

139 |

√ |

√ |

|

|

Sn64Bi35Ag1 |

139 |

187 |

√ |

√ |

|

|

Sn64.7Bi35Ag0.3 |

139 |

187 |

√ |

|

|

Lead |

Sn63Pb37 |

183 |

183 |

√ |

√ |

|

|

Sn60Pb40 |

183 |

188 |

√ |

|

|

|

Sn62Pb36Ag2 |

179 |

179 |

√ |

|

|

|

Sn43Pb43Bi14 |

135 |

165 |

√ |

|

|

|

Sn5Pb92.5Ag2.5 |

296 |

301 |

√ |

√ |

|

|

Sn5Pb95 |

308 |

312 |

√ |

√ |

|

Note: Other alloy specifications can be customized according to user requirements. |

|||||

|

|

|||||

|

Water-Soluble Solder Paste |

|||||

|

Type |

Alloy Composition |

Tin Powder Particle Size |

Packaging Format |

||

|

|

|

|

|

||

|

Lead-free |

SnAgCu |

Type4, Type5, Type6 |

Jars/Syringes |

||

|

|

SnBiX |

|

|

||

|

Lead |

Sn63Pb37 |

|

|

||

|

Features |

|||||

|

1. Excellent printability for microbump and fine-pitch micro-component packaging. |

|||||

|

2. Superior solderability on various pads with strong QFN solder wetting performance. |

|||||

|

3. Effective aqueous cleanability meeting high-reliability requirements. |

|||||

|

4. Minimal voiding effects on BGA and chip ground pads. |

|||||

|

5. Robust anti-slump properties and thixotropic behavior suitable for printing, jetting, pin transfer, and dispensing. |

|||||

|

6. Compliant with RoHS and halogen-free environmental regulations. |

|||||

|

|

|||||

|

Spray-Applied Solder Paste |

|||||

|

Type |

Alloy Composition |

Tin Powder Particle Size |

Packaging Format |

||

|

|

|

|

|

||

|

Lead-free |

SnAgCu |

Type4, Type5, Type6 |

10g, 20g, 50g, 100g |

||

|

|

SnBiX |

|

|

||

|

Lead |

SnPbX |

|

|

||

|

Features |

|||||

|

1. Superior solder powder morphology with high sphericity and narrow particle size distribution. |

|||||

|

2. Exceptional flow consistency featuring uniform deposition, consistent joint formation, and precise paste definition. |

|||||

|

3. Extended process stability supporting prolonged spray operations and multiple freeze-thaw cycles without performance degradation. |

|||||

|

4. High flux activity delivering bright, well-formed solder joints with excellent fillet integrity. |

|||||

|

|

|||||

|

Lazer Solder Paste |

|||||

|

Type |

Alloy Composition |

Tin Powder Particle Size |

Packaging Format |

||

|

|

|

|

|

||

|

Lead-free |

SnAgCu |

Type4, Type5, Type6 |

10g, 20g, 50g, 100g |

||

|

|

SnBiX |

|

|

||

|

Lead |

SnPbX |

|

|

||

|

Features |

|||||

|

1. Rapid flux activation with laser-enhanced wetting performance. |

|||||

|

2. Exceptional stability supporting extended dispensing operations and multiple freeze-thaw cycles. |

|||||

|

3. Consistent deposition integrity: Continuous dispensing without breakage & Precise shape retention. |

|||||

|

4. High post-soldering insulation resistance. |

|||||

|

|

|||||

|

LED-Specific Solder Paste |

|||||

|

Type |

Alloy Composition |

Features & Applications |

|||

|

|

|

|

|||

|

Lead |

Sn60Pb40 |

Tin-lead paste with good solderability and tombstoning resistance. |

|||

|

|

Sn63Pb37 |

Mainstream lead solder with high joint strength, stable and reliable quality. |

|||

|

|

Sn62.8PbAg0.4 |

Mainstream lead solder with tombstoning resistance, higher joint strength than Sn60Pb40, primarily for high-density LED displays. |

|||

|

Tin-Bismuth |

SnBi58 |

Lead-free & eco-friendly, meets low-temperature soldering requirements. |

|||

|

|

SnBi57Ag1 |

Lead-free & eco-friendly, Sn-Bi-Ag alloy, higher joint strength than SnBi58, meets low-temperature requirements. |

|||

|

|

SnBi35Ag1 |

Lead-free & eco-friendly, mid-temperature paste, higher joint strength than SnBi57Ag1. |

|||

|

Lead-free |

SnAg3.0Cu0.5 |

Mainstream lead-free solder with high joint strength, excellent reliability, high thermal conductivity, for high-temperature LED SMT. |

|||

|

|

SnAg1.0Cu0.5 |

|

|||

|

|

SnAg0.3Cu0.7 |

|

|||

|

Features |

|||||

|

1. Superior solderability across various PCB finishes. |

|||||

|

2. Low voiding (<15%) with enhanced electrical/thermal conductivity and high shear strength. |

|||||

|

3. Minimal post-reflow residue exhibiting light coloration and high SIR. |

|||||

|

4. High first-pass yield with strong self-alignment during reflow. |

|||||

|

|

|||||

|

Photovoltaic (PV) Specialty Solder Paste |

|||||

|

Type |

Alloy Composition |

Tin Powder Particle Size |

Packaging Format |

||

|

|

|

|

|

||

|

Lead-free |

SnAg0.3Cu0.7 |

Type3, Type4, Type5, Type6 |

100g, 200g, 500g |

||

|

Lead |

Sn63Pb37 |

|

|

||

|

Features |

|||||

|

1. Broad reflow process window ensuring reliable soldering. |

|||||

|

2. Excellent solderability with high post-reflow yield, minimizing surface tension effects. |

|||||

|

3. Low residue, high insulation resistance, and stable electrical performance. |

|||||

|

4. Consistent viscosity with optimal flow properties for stable printing/dispensing. |

|||||

Packaging of Solder Paste:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

here

for

price