- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Galvalume Steel Coil For Roofing

Thickness: 0.16mm - 2.5mm

Width: 600mm - 1500mm

Coating Weight: AZ30 to AZ185

Specifications of Galvalume Steel Coil:

1) Capacity: about 10,000 ton per month for galvalume steel

2) Standard: JIS3321/ASTM A792M

3) Thickness: 0.16mm - 2.5mm, all available

4) Width: 600mm - 1500mm, all available

5) Length: according to the customer's request

6) Coil ID: 508/610mm

7) Coil weight: according to the customer's request

8) Coating Weight: AZ30 to AZ185

9) Spangle: regular spangle, small spangle, big spangle

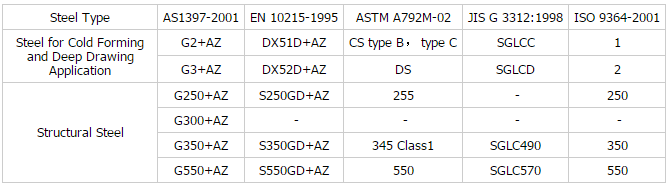

10) Steel Type & Grade:

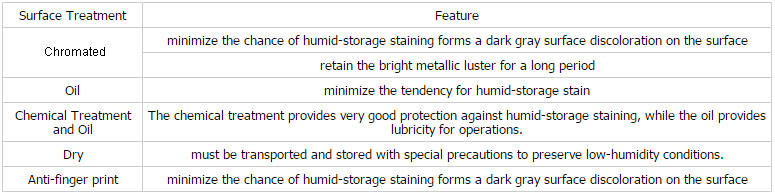

11) Surface Treatment:

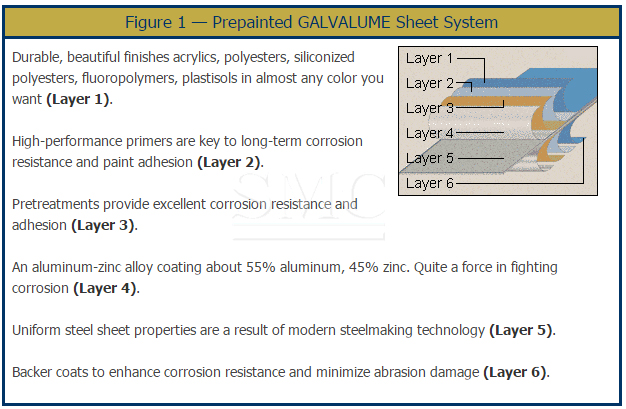

Shanghai Metal, the manufacturer of prepainted GALVALUME sheet panels, starts with the GALVALUME steel substrate and its exceptionally corrosion-resistant aluminum-zinc alloy coating. Next, this high-performance coated steel passes through modern high-speed continuous coil coating lines that carefully apply and oven-cure the paint systems. The painted product is made to rigid specifications and quality-tested to meet critical laboratory performance requirements established by ASTM. After painting, the coils are ready for forming into versatile, eye-catching roofing and siding panels.

Finishes

Prepainted GALVALUME sheet is supplied with a factory-applied, baked-on finish. Processing on the paint line includes cleaning, pretreating, priming and top coating with a uniform paint finish, all in one continuous process. A schematic diagram of the prepainted GALVALUME sheet system is shown in Figure 1 (below). GALVALUME sheet, with its highly corrosion-resistant aluminum-zinc coating, serves as the foundation for the paint system. A chemical pretreatment is applied to promote adhesion between the paint and metal coating surface. A high-performance primer is applied to the pretreated surface to enhance corrosion resistance, particularly at cut edges, scratches and bends. The system is completed by applying a colorful, durable paint selected for the performance requirements of the application. Typical topcoats include acrylics, polyesters, siliconized polyesters, fluoropolymers and plastisols.

It is recommended that the unexposed or back side be pretreated, primed and coated with a 'backer' coat. The backer coat is applied to enhance performance and appearance, and to minimize abrasion during shipping and handling. The back side may be coated with a full paint system similar to the exposed side. Refer to paint manufacturers for specific recommendations.

Rollforming

Sheet Fed Coils

Rollforming is most commonly used to form prepainted GALVALUME sheet into roofing and siding panels. Rollformers consist of a series of shaped rolls mounted on stands that progressively form the sheet fed from a coil into panel profiles.

Prepainted GALVALUME sheet can be readily formed into an almost limitless variety of shapes and profiles, depending on the strength and ductility of the GALVALUME sheet, the characteristics of the paint system, and the type of rollforming equipment and its maintenance.

Good Practice Guidelines for Rollforming Prepainted GALVALUME Sheet

Use panel designs with large bend radii. It is possible to design architecturally desirable, deep profiles, and at the same time, use large bend radii.

Design the rollformer so that profiling occurs from the center of the sheet out towards the edges.

Design the rollformer to accommodate the strength of the steel grade. For example, a higher strength steel may require more rollformer stands to successfully produce a given profile.

Use lower strength steels to allow greater design latitude when making more complex profiles.

Maintain the rollforming equipment to achieve proper vertical and horizontal tooling alignment, as well as adequate clearance between the mating top and bottom spindle rolls to avoid abrading the coating. Clean the rolls to avoid damage to the paint finish.

Incorporate the appropriate number of rollforming stages to ensure smooth transitioning of bends.

Use flexible paint/primer systems to maximize performance at bends.

Other Types of Forming

Rollforming is by far the most common type of forming for prepainted GALVALUME sheet. However, for applications where prepainted GALVALUME sheet is used for wall and/or roof panels, there will very likely be a need to press-brake form trim parts and other accessories. Again, it is important to use the maximum permissible bend radii to enhance the performance at bends.

Equally important for press-brake forming is the need to protect the painted surface from scratches and abrasion. This can be accomplished by using polyurethane or a similar hard plastic material for the dies. Proper tooling clearances should be maintained during this operation.

Roofs

Roll embossing is another type of forming that can be applied to prepainted GALVALUME sheet. Care must be exercised to assure that the paint and metallic GALVALUME coating are not damaged during embossing. The depth and sharpness of the embossment should be sufficiently gentle to assure that the durability of prepainted GALVALUME sheet is not compromised.

Other types of forming, including stamping, notching and piercing can be applied to prepainted GALVALUME sheet. Many of the factors discussed previously, such as die clearance and good paint system flexibility, are equally important considerations for these types of forming. For example, stamping is used to form prepainted GALVALUME facsimile roof tile panels, mainly used for residential roofing.

Packaging of Galvalume Steel Coil

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Galvalume Steel Coil:

1) Construction: roofing, cladding, structural sections, composite panels, etc.

2) Electric appliance: washing machine, refrigerators, toaster, microwave, etc.

3) Others: air duct, lighting, computer casing, etc.

Features of Galvalume Steel Coil:

1) Composed of 55% aluminum, 43.5% zinc and 1.5% silicon

2) Formable, weldable and paintable

3) Superior corrosion resistance in the most atmospheric conditions. This is achieved through the combination of the sacrificial protection of the zinc and the barrier protection of the aluminum

4) Coating out-performs galvanized coating from 2-6 times than hot dip galvanized steel

here

for

price