- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

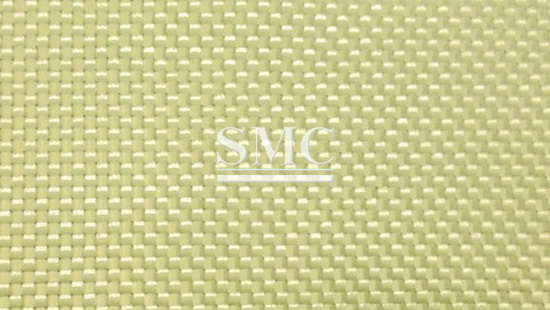

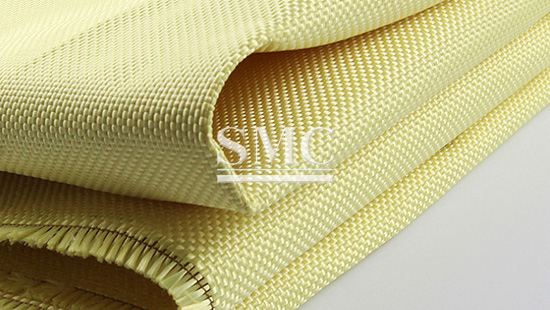

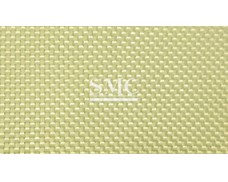

Aramid FRP Sheet / Kevlar Fabric

Size: Max. Width 3200mm

Weight: 60/100/120/240/400 g/m2

Surface: Plain, satin, 2x2 twill, etc

Material: DuPont® Kevlar® fiber

Shanghai Metal Corporation is a leading manufacturer and supplier of Aramid FRP Sheet / Kevlar Fabric in China.

The Kevlar® fabric is relatively lightweight, has moderate tensile and compressive strength and is easy to handle and machine. High strength, dimensional stability, design flexibility and excellent electrical properties. The products mainly used in military, aerospace, industrial protection where require high temperature resistance, wear resistance and high strength.

If you want to know more about Aramid FRP Sheet / Kevlar Fabric or other related fabric, please feel free to contact us, we will reply you within 24 hours.

Material introduction

Kevlar® Fiber, produced by DuPont, is a new high-tech synthetic fiber, with ultra-high strength, high modulus and high temperature resistance, acid and alkali resistance, light weight and other excellent properties, its strength is 10 times of ordinary polyester material, 5 to 6 times of steel wire, modulus is 2 to 3 times of steel wire or glass fiber, toughness is 2 times of steel wire. The weight is only about 1/5 of the steel wire, and it does not decompose and melt at a temperature of 560 degrees. It has good insulation and anti-aging properties, and also has an extremely long life cycle.

1. Light in Weight, High in Performance — Kevlar® Fiber

Versatile and strong, Kevlar® fiber is more than just a series of threads. DuPont™ Kevlar® fibers are used in a variety of clothing, accessories, and equipment to help make them safer and more durable. With five times the strength of steel based on an equal weight basis, it’s the go-to fiber for protective apparel and accessories.

Kevlar® fiber and filament come in a variety of types, each with its own unique set of properties and performance characteristics for different protection needs.

2. Kevlar® AP

A next-generation fiber that offers advanced performance, value, and increased design flexibility in many applications.

3. Kevlar® 29 (K29)

The original family of product types of Kevlar®, having similar tensile properties with many deniers and finishes. These yarns are used in ballistic applications, ropes and cables, protective apparel such as cut-resistant gloves, in life protection uses such as helmets, vehicular armoring, and plates, and as rubber reinforcement in tires and automotive hoses.

4. Kevlar® 49 (K49)

High-modulus type used primarily in fiber optic cable, textile processing, plastic reinforcement, ropes, cables, and composites for marine sporting goods and aerospace applications.

5. Kevlar® 100

Producer-colored Kevlar® yarns, used in ropes and cables, tapes and strappings, gloves and other protective apparel, and sporting goods.

6. Kevlar® 119

Higher-elongation, flexible-fatigue–resistant yarn types found in mechanical rubber goods, such as tires, automotive belts, and hoses.

7. Kevlar® 129

Lightweight, high-performance, and high-tenacity type of yarns used in motorcycle racing gear, life protection accessories, ropes and cables, and high-pressure hoses used in the oil and gas industry.

8. Kevlar® KM2

Woven into fabric meeting performance requirements for helmets and vests for military and high-performing UDs for spall liners.

9. Kevlar® KM2 Plus

High tenacity, high toughness, and finer denier fiber used in vests and helmet for both military and law enforcement officers.

10. Kevlar® AP

Kevlar® AP for Advanced Performance helps dramatically improve cost-effectiveness and design flexibility to manufacturers helping them build leaner, more robust consumer and industrial products.

Packaging of Aramid FRP Sheet / Kevlar Fabric

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. Foam Paper carton, Pearl cotton carton, Wooden Pallet is adopted. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Common Properties

Excellent durability:

Kevlar aramid fabric has excellent friction and chemical resistance. After 100 times of washing, the tearing strength of the fabric processed with para-aramid can still reach more than 85% of the original strength.

Good mechanical properties:

Kevlar para arlon is a flexible polymer, the breaking strength is much higher than ordinary polyester, cotton, nylon, etc., the elongation is large, soft feel, spinnability is good, can be produced into different sizes, lengths of staple fiber and filament, in the general textile machinery made of different yarn woven fabric, non-woven fabric, after finishing, to meet the requirements of different fields of protective clothing.

Stable chemical properties:

Kevlar aramid fabric has excellent resistance to most chemical substances, can withstand most high concentrations of inorganic acids, good alkali resistance at room temperature.

Excellent radiation resistance:

Kevlar aramid fabric has excellent radiation resistance. For example, under the long-term irradiation of 1.2×10-2 w/in2 ultraviolet rays and 1.72×108rads of gamma rays, its intensity remains unchanged.

Excellent flame retardant and heat resistance:

Kevlar aramid fiber has a limiting oxygen index (LOI) greater than 28, so it does not continue to burn when it leaves the flame.The flame retardant properties of Kevlar arylon cloth are determined by its own chemical structure, so it is a flame retardant fiber cloth, which will not reduce the flame retardant performance due to the use time and washing times. Kevlar aramid fabric has good thermal stability, can be used continuously under the condition of 300 ° C, and can still maintain high strength under high temperature conditions greater than 300 ° C; Meta-aramid has a high decomposition temperature, and will not melt and melt drop under high temperature conditions, when the temperature is greater than 427℃ to start carbonization.

here

for

price