- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

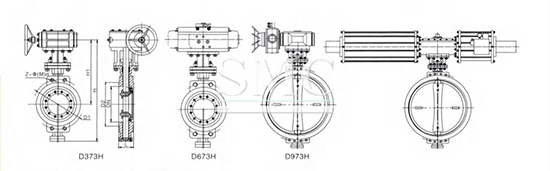

Butterfly Valve

Material: Carbon steel, Stainless steel, Alloy steel...

Size: DN50 - DN1200

Type: Single-eccentric center, Center line-type, Double-eccentric,Three-eccentric, Link-eccentric

Suitable medium: Water, Steam, Oil products, Seawater...

Shanghai Metal Corporation is a professional manufacturer and supplier of Butterfly Valve with high quality and reasonable price.

The main functions of butterfly valves include regulating flow, regulating pressure, preventing reverse flow, and changing flow direction. Butterfly valves regulate the flow rate of the medium in the pipeline by adjusting the opening of the butterfly plate, achieving flow control of the fluid. When the closure degree of the butterfly plate increases, the flow rate in the pipeline is restricted, thus enabling control of the medium pressure. In addition, butterfly valves can automatically close to prevent the reverse flow of the medium and protect the pipeline system. By changing the position of the butterfly plate, the direction of medium flow can be changed, thereby controlling the flow of the pipeline system.

If you want to know more about Butterfly Valve price please feel free to contact us, we will reply you within 24 hours

Technical Information of Butterfly Valve:

|

Nominal diameter |

150Lb |

||||||

|

Inch |

mm |

L(mm) |

H(mm) |

H1(mm) |

D1(mm) |

D2(mm) |

N-φ(M)d(mm) |

|

2 |

50 |

43 |

300 |

210 |

120.5 |

92 |

4-19 |

|

3 |

80 |

49 |

340 |

230 |

152.5 |

127 |

4-19 |

|

4 |

100 |

54 |

400 |

265 |

190.5 |

157 |

4-19 |

|

5 |

125 |

57 |

480 |

325 |

216 |

186 |

4-22 |

|

6 |

150 |

58 |

530 |

345 |

241.5 |

216 |

4-22 |

|

8 |

200 |

64 |

620 |

395 |

298.5 |

270 |

4-22 |

|

10 |

250 |

71 |

680 |

425 |

362 |

324 |

4-25 |

|

12 |

300 |

81 |

800 |

495 |

432 |

381 |

4-25 |

|

14 |

350 |

92 |

880 |

555 |

476 |

413 |

4-29 |

|

16 |

400 |

102 |

950 |

590 |

540 |

470 |

4-(1) |

|

18 |

450 |

114 |

1000 |

630 |

578 |

533 |

4-(11/8) |

|

20 |

500 |

127 |

1110 |

700 |

635 |

584 |

4-(11/8) |

|

24 |

600 |

154 |

1230 |

750 |

749.5 |

692 |

4-(11/4) |

|

28 |

700 |

165 |

1350 |

810 |

795.3 |

762 |

8-(3/4) |

|

32 |

800 |

190 |

1390 |

840 |

900.1 |

864 |

8-(3/4) |

|

36 |

900 |

203 |

1660 |

1000 |

1009.6 |

972 |

8-(7/8) |

|

40 |

1000 |

216 |

1720 |

1080 |

1120.8 |

1080 |

8-(1) |

|

48 |

1200 |

254 |

2080 |

1250 |

1335.1 |

1289 |

8-(11/8) |

Packaging of Butterfly Valve:

Products of Shanghai Metal Corporation are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

NOTICE:

1. Confirm the flow direction of the medium: When installing butterfly valves, it is necessary to ensure that the flow direction of the medium is consistent with the direction of the arrow to ensure the normal operation of the valve. For example, when installing on a horizontal pipeline, the valve stem should be installed vertically upwards or tilted at a certain angle, but never downwards. At the same time, for valves in grooves with cover plates, the convenience of installation, maintenance, and operation should be fully considered.

2. Reserve sufficient space: To facilitate inspection and maintenance, ensure that there is enough space above and below the butterfly valve. If a flange connected valve body is used, it is necessary to ensure that the flange surface is accurately aligned, so that the gasket surface contacts evenly, thereby preventing leakage.

Avoid Additional Stress: During installation, avoid applying excessive stress to the valve, such as over-tightening connection bolts or forcibly twisting the valve. Follow the specified torque values to evenly tighten bolts and ensure proper alignment between the pipeline and the valve. This prevents damage to the valve caused by misalignment.

here

for

price