- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

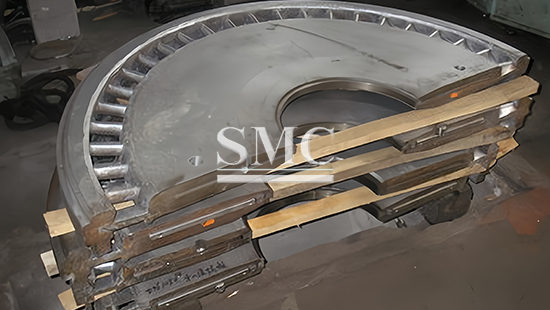

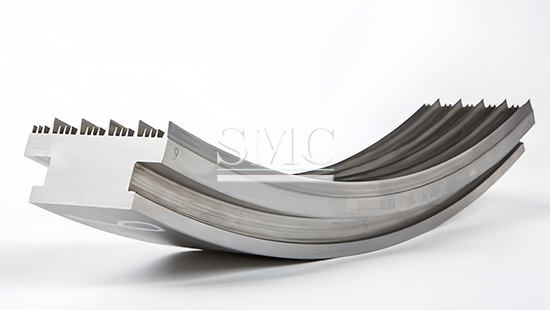

Steam Turbine Diaphragm

Material: High - Performance Alloy Steel 40Cr, 35CrMo, 60Si2Mn

Advantage: Corrosion Resistant, High Load Capacity, Easy Installation

Type: Casting Diaphragm, Welding Diaphragm, Assembled Diaphragm

Shanghai Metal Corporation is a preeminent Steam Turbine Diaphragm manufacturer and supplier.

Our Steam Turbine Diaphragms, masterfully crafted from premium high - performance alloy steel such as 40Cr, 35CrMo, and 60Si2Mn, stand as a testament to reliability and top - tier performance across an extensive spectrum of power generation and industrial conditions. These diaphragms are meticulously designed to withstand the harshest mechanical and thermal stresses, be it the intense pressure differentials and high - velocity steam forces in power generation turbines or the variable operational loads in industrial steam - driven equipment.Turbine Diaphragms from Shanghai Metal Corporation are engineered to serve a wide array of applications. In large - scale power plants, they play a pivotal role in guiding the steam flow between different stages of turbines. This precise steam - flow regulation is crucial for optimizing the energy conversion process, ensuring efficient and stable power generation. For instance, in coal - fired power plants, our diaphragms help direct the high - pressure steam through the turbine blades, maximizing the extraction of mechanical energy from the steam and ultimately enhancing the power output.

If you want to know more about our Steam Turbine Diaphragms, please feel free to contact us. We will reply to you within 24 hours.

Technical Information of Steam Turbine Diaphragm:

|

Basic parameters of various models of National Five engines |

||||

|

model |

horsepower |

Maximum torque Nm |

Maximum torque speed r/min |

Economic speed r/min |

|

WP12 |

460 |

2110 |

1000~1400 |

1100~1400 |

|

430 |

2060 |

1000~1400 |

1100~1400 |

|

|

400 |

1920 |

1000~1400 |

1100~1400 |

|

|

375 |

1800 |

1000~1400 |

1100~1400 |

|

|

WP13 |

480 |

2400 |

900~1400 |

1100~1300 |

|

500 |

2400 |

900~1400 |

1100~1300 |

|

|

530 |

2500 |

900~1400 |

1100~1300 |

|

|

550 |

2550 |

900~1400 |

1100~1300 |

|

|

WP9H |

290 |

1400 |

1000~1400 |

1100~1300 |

|

310 |

1500 |

1000~1400 |

1100~~1300 |

|

|

336 |

1600 |

1000~1400 |

1100~~1300 |

|

|

350 |

1700 |

1100~1400 |

1100~1300 |

|

|

|

Inlet pressure(Rated working condition) kPa |

Inlet pressure(Large torque condition) kPa |

Intake valve clearance (mm) |

EVB clearance mm (assembly) |

|

WP12 |

272 |

268 |

0.4 |

0.40±0.03 |

|

266 |

260 |

0.4 |

0.40±0.03 |

|

|

257 |

253 |

0.4 |

0.40±0.03 |

|

|

253 |

245 |

0.4 |

0.40±0.03 |

|

|

WP13 |

270 |

259 |

0.4 |

0.4 |

|

278 |

269 |

0.4 |

0.4 |

|

|

286 |

274 |

0.4 |

0.4 |

|

|

287 |

280 |

0.4 |

0.4 |

|

|

WP9H |

269 |

273 |

0.4 |

none |

|

272 |

280 |

0.4 |

none |

|

|

276 |

287 |

0.4 |

none |

|

|

279 |

289 |

0.4 |

none |

|

|

|

Exhaust valve clearance mm |

|||

|

WP12 |

0.6 |

|||

|

0.6 |

||||

|

0.6 |

||||

|

0.6 |

||||

|

WP13 |

0.6 |

|||

|

0.6 |

||||

|

0.6 |

||||

|

0.6 |

||||

|

WP9H |

0.5(Exhaust rocker arm Foot and exhaust valve bridge) 1.35(Exhaust rocker arm (at the moving valve) 0(Exhaust rocker arm ball pin Flange surface and rocker arm bottomnoodle) |

|||

Packaging of Turbine Diaphragm:

Shanghai Metal Corporation is committed to ensuring that all steam turbine diaphragms are packaged and labeled in strict accordance with industry norms and customer - specific demands. We place significant emphasis on safeguarding the diaphragms during transit and storage, employing robust packaging materials and distinct labeling for effortless identification. Tailored packaging solutions are also accessible upon request.

1)Shanghai Metal Standard

Inner Packaging;

Cushioning Layer;

Outer Packaging;

Labeling;

2)Customization

Specialty Packaging;

Custom Labeling;

Assembly - Ready Packaging;

here

for

price