- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

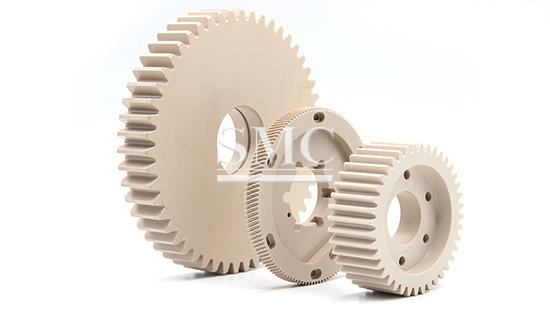

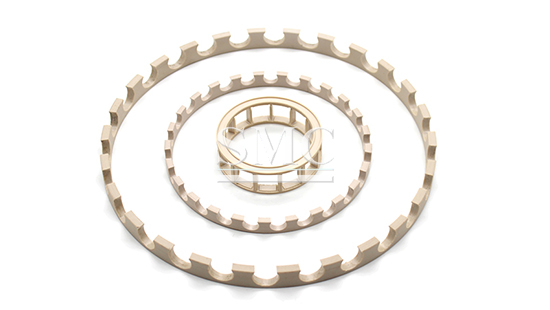

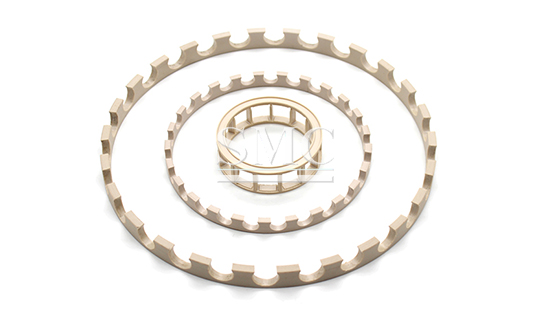

PEEK Gear

Material: PEEK 5600G, PEEK5600CF30, PEEK5600GF30, PEEK5600LF30, PEEK5600FE20

Color: Natural grey, black

Size: customized

MOQ: 1 PC

Shanghai Metal Corporation is a leading PEEK gear manufacturer and supplier.

Polyetheretherketone (PEEK) is a special engineering plastic that can withstand high temperatures (continuous use at 480°F), has high mechanical strength, and is self-lubricating. It also features wear resistance, corrosion resistance, radiation resistance, and flame retardancy.

PEEK gears can be injection molded, so they offer many advantages in design, processing and performance compared to traditional materials. The inherent design freedom of PEEK molding ensures more efficient gear manufacturing. PEEK can be used to form internal gears, gear sets, worm gears and other products. PEEK gears have broader application prospects than traditional gears. Therefore, PEEK materials promote the development of gears to withstand higher loads and transmit greater power.

If you want to know more about our PEEK products or PEEK gear price please feel free to contact us, we will reply you within 24 hours.

|

Mechanical performance |

|

|

|

|

|

|

|

|

Item |

Test StandardOr Instrument |

Unit |

PEEK5600G |

PEEK5600CF30 |

PEEK5600GF30 |

PEEK5600LF30 |

PEEK5600FE20 |

|

100%PEEK |

PEEK+30%CF |

PEEK+30%GF |

PEEK+30%(CF+G+PTFE) |

PEEK+20%PTFE |

|||

|

Tensile strength(23C) |

ISO527 |

MPa |

90 |

210 |

155 |

134 |

68 |

|

Bending strength(23°C) |

ISO178 |

MPa |

163 |

298 |

212 |

186 |

118 |

|

Compress strength(23C) |

ISO604 |

MPa |

118 |

240 |

215 |

150 |

105 |

|

CHARPY Impact Strength(unnotched) |

ISO179/1U |

KJ/m² |

No Break |

40 |

51 |

32 |

47 |

|

lzodnotched lmpact Strength(notched |

ISO180/A |

KJ/m² |

7 |

9 |

8 |

5 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Thermal performance |

|

|

|

|

|

|

|

|

Item |

Test Standard Or Instrument |

Unit |

PEEK5600G |

PEEK5600CF30 |

PEEK5600GF30 |

PEEK5600LF30 |

PEEK5600FE20 |

|

100%PEEK |

PEEK+30%CF |

PEEK+30%GF |

PEEK+30%(CF+G+PTFE) |

PEEK+20%PTFE |

|||

|

Melting point |

IS0 11357 |

℃ |

343 |

343 |

343 |

343 |

343 |

|

Heat deflection temperature |

ISO 75-f |

℃ |

163 |

315 |

315 |

293 |

/ |

|

Temperature Renge |

UL 74685 |

℃ |

260 |

260 |

260 |

260 |

240 |

|

coefficient of thermalexpansion |

ASTM D696 |

10-6℃ |

4.7 |

1.5 |

2.2 |

2.2 |

6 |

|

Flammability Rating |

UL94 |

V-0@mm |

1.5 |

1.5 |

1.5 |

0.75 |

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrical performance |

|

|

|

|

|

|

|

|

Item |

|

Unit |

PEEK5600G |

PEEK5600CF30 |

PEEK5600GF30 |

PEEK5600LF30 |

PEEK5600FE20 |

|

|

100%PEEK |

PEEK+30%CF |

PEEK+30%GF |

PEEK+30%(CF+G+PTFE) |

PEEK+20%PTFE |

||

|

Density |

ISO 1183 |

g/cm³ |

1.3±0.02 |

1.4±0.02 |

1.5±0.02 |

1.43±0.02 |

1.41 |

|

Rockwell hardnesss |

IS0 2039 |

HRE |

50 |

80 |

70 |

40 |

50 |

|

Coefficient of friction |

ASTM D3702 |

/ |

0.30-0.38 |

0.28 |

0.38-0.46 |

0.18 |

0.17-0.20 |

|

Water absorption |

ISO 62 |

% |

0.15 |

0.06 |

0.11 |

0.06 |

0.15 |

|

Mold shrinkage |

3mm厚度,170°C流动方向3mm,170°C |

% |

1.2 |

0.1 |

0.4 |

0.3 |

1.3 |

|

(25-24℃) |

重直于流动方向(饱和结晶大些) |

% |

1.5 |

0.5 |

0.8 |

0.5 |

1.8 |

Packaging of PEEK gear

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

here

for

price