- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

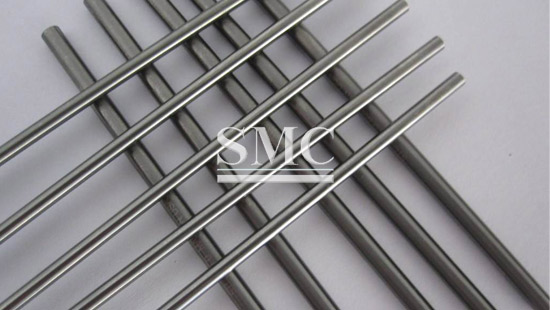

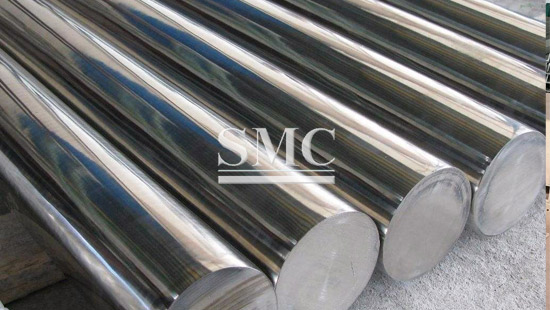

High Speed Steel (HSS) Bar & Tool Steel Bar

Shape: Round bar, flat bar, sheet

Grade: M2, M7, M35, M42, etc

High speed steel is a tool steel with high hardness, high wear-resistance and high heat resistance, which is known as high-speed tool steel or white steel.

Shanghai Metal Corporation is the leading manufacturer of High Speed Steel (HSS) Bar & Tool Steel Bars in the world. With totally controlling the quality properties such as chemical composition, carbide shape, surface decarburization, size precision, especially alloy content, carbon saturation, composition dispersion coefficient and purity, we put our quality management into a tight combination with customers demand and practical application to offer a guarantee to customers in the reliability and identity of heat treatment performance and utilization property.

If you want to know more about our steel products or High Speed Steel(HSS)Bar & Tool Steel Bar price please feel free to contact us, we will reply you within 24 hours.

Grade Contrast Table:

|

Tool Steel Round Bar |

Grade |

Size Rage |

|

|

DIN |

AISI |

||

|

1.2344 |

H13 |

15-580 mm |

|

|

1.2343 |

H11 |

15-505 mm |

|

|

1.2379 |

D2 |

15-380 mm |

|

|

1.2365A |

H10 |

15-450 mm |

|

|

1.2365B |

H10A |

15-450 mm |

|

|

1.2367 |

- |

15-450 mm |

|

|

1.2363 |

A2 |

15-300 mm |

|

|

1.2080 |

D3 |

15-200 mm |

|

|

1.2510 |

O1 |

15-300 mm |

|

|

1.2083 |

- |

15-300 mm |

|

|

1.2714 |

L6 |

15-350 mm |

|

|

1.2767 |

- |

15-300 mm |

|

|

1.2436 |

D6 |

15-130 mm |

|

|

Product |

Grade |

Size Rage |

|

|

DIN |

AISI |

||

|

Tool Steel Flat Bar |

1.2344 |

H13 |

Width: 300-810 mm Thickness: 14-120 mm |

|

1.2343 |

H11 |

Width: 300-810 mm Thickness: 14-120 mm |

|

|

1.2379 |

D2 |

Width: 300-810 mm Thickness: 14-100 mm |

|

|

1.2510 |

O1 |

Width: 300-810 mm Thickness: 14-100 mm |

|

|

1.2365 |

H10 |

Width: 300-810 mm Thickness: 14-100 mm |

|

|

1.2367 |

- |

Width: 300-810 mm Thickness: 14-100 mm |

|

|

1.2842 |

O2 |

Width: 300-810 mm Thickness: 14-100 mm |

|

|

1.2363 |

A2 |

Width: 300-810 mm Thickness: 14-100 mm |

|

|

1.2083 |

- |

Width: 300-810 mm Thickness: 14-100 mm |

|

|

1.2360 |

A8 |

Width: 300-810 mm Thickness: 14-100 mm |

|

|

1.2080 |

D3 |

Width: 300-600 mm Thickness: 14-80 mm |

|

Specification of High Speed Steel:

|

Specification of High Speed Steel |

||||

|

Product |

Grade |

Size Rage |

||

|

DIN |

AISI |

JIS |

||

|

HSS Round Bar |

1.3343 |

DINM2 |

- |

2.5-205 mm |

|

1.3243 |

M35 |

SKH51 |

2.5-160 mm |

|

|

1.3247 |

M42 |

SKH2 |

15-65 mm |

|

|

1.3346 |

M1 |

- |

2.5-205 mm |

|

|

1.3392 |

M52 |

- |

2.5-205 mm |

|

|

- |

M4 |

- |

15-80 mm |

|

|

- |

M7 |

SKH58 |

15-80 mm |

|

|

- |

W9 |

- |

3.6-160 mm |

|

|

HSS Square Bar |

1.3343 |

DINM2 |

- |

15-40 mm |

|

1.3244 |

M35 |

SKH59 |

15-40 mm |

|

|

1.2344 |

H13 |

SKD62 |

120-250 mm |

|

|

1.2367 |

- |

- |

120-180 mm |

|

|

HSS Flat Bar |

1.3343 |

M2 |

SKH51 |

With: 100-510 mm Thickness: 14-65 mm |

Chemical Composition of High Speed Steel:

|

Chemical Corporation of High Speed Steel (%) |

||||||||

|

Grade |

C |

Si |

Mn |

W |

Mo |

Cr |

V |

Others |

|

W9Mo3Cr4V |

0.77-0.87 |

0.20-0.40 |

0.20-0.40 |

8.50-9.50 |

2.70-3.30 |

3.80-4.40 |

1.30-1.70 |

- |

|

W6Mo5Cr4V2 |

0.80-0.90 |

0.20-0.45 |

0.15-0.40 |

5.50-6.75 |

4.50-5.50 |

3.80-4.40 |

1.75-2.20 |

- |

|

Din M2 |

0.86-0.94 |

≤0.45 |

≤0.40 |

6.00-6.70 |

4.70-5.20 |

3.80-4.50 |

1.70-2.00 |

- |

|

W6Mo5Cr4V2Al(M2Al) |

1.05-1.20 |

0.20-0.60 |

0.15-0.40 |

5.50-6.75 |

4.50-5.50 |

3.80-4.40 |

1.75-2.20 |

Al: 0.80-1.20 |

|

W6Mo9Cr4V2 |

0.97-1.05 |

0.20-0.55 |

0.15-0.40 |

1.40-2.10 |

8.20-9.20 |

3.50-4.00 |

1.75-2.20 |

- |

|

W6Mo5Cr4V2Co5(M35) |

0.88-0.96 |

0.25-0.45 |

0.20-0.40 |

6.00-6.70 |

4.70-5.20 |

3.80-4.50 |

1.70-2.00 |

Co: 4.50-5.50 |

|

W2Mo9Cr4VCo8(M42) |

1.05-1.15 |

0.15-0.65 |

0.15-0.40 |

1.15-1.85 |

9.00-10.00 |

3.50-4.25 |

0.95-1.35 |

Co: 7.75-8.75 |

|

W18Cr4V(W18) |

0.70-0.80 |

0.20-0.40 |

0.10-0.40 |

17.50-19.00 |

≤0.3 |

3.80-4.40 |

1.00-1.40 |

- |

|

W4Mo3Cr4VSi(W4) |

0.88-0.98 |

0.50-1.00 |

0.20-0.40 |

3.50-4.50 |

2.50-3.50 |

3.80-4.40 |

1.20-1.80 |

- |

|

W4Mo2Cr4VSi(T-4241) |

0.90-1.00 |

0.80-1.30 |

0.20-0.45 |

1.50-2.50 |

0.50-1.20 |

3.80-6.00 |

0.50-1.00 |

- |

|

H13(4CrMoSiV1) |

0.32-0.45 |

0.80-1.20 |

0.20-0.50 |

- |

1.10-1.75 |

4.75-5.50 |

0.80-1.20 |

- |

|

Cr12Mo1V1 |

1.40-1.60 |

≤0.60 |

≤0.60 |

- |

0.70-1.20 |

11.00-13.00 |

0.50-1.10 |

- |

|

3Cr2W8V |

0.30-0.40 |

≤0.40 |

≤0.40 |

7.50-9.00 |

- |

2.20-2.70 |

0.20-0.50 |

- |

|

9Cr18MoV |

0.85-0.95 |

≤0.80 |

≤0.80 |

- |

1.00-1.30 |

17.00-19.00 |

0.07-0.12 |

- |

|

9Cr18Mo |

0.95-1.10 |

≤0.80 |

≤0.80 |

- |

0.40-0.70 |

16.00-18.00 |

- |

- |

|

9Cr18 |

0.90-1.00 |

≤0.80 |

≤0.80 |

- |

≤0.75 |

17.00-19.00 |

- |

- |

Packaging of High Speed Steel:

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

Application of High Speed Steel:

- High Speed Steel is generally used for machining tools and manufacture of forming tools

- Broaches

- Drill bit

- Reamer

- Milling cutter

- Pin

- Saw

- knife

- Punches, etc

|

Breed |

Durability/Cutting Strength |

Remark |

||

|

Normal |

Higher |

Top High |

||

|

Drill |

M2, W9, HYW6-A |

M35, M42 |

AHP30 |

DIY Drills, HYW4, HY607, Big Size Taper Shank Drills, HYW6-A |

|

End Mill |

M2, W9 |

M42, M2Al |

AHPM4, AHPT15 |

Nickel-Base Alloy and Titanium, AHPM3 |

|

Tap |

M2 |

M35 |

AHPM3, AHP30 |

- |

|

Gear Cutter |

M2 |

M35, M42, AHPM4 |

AHPT15M |

Gear Shaver, AHPM4 |

|

Broach |

M2 |

M42, M2Al |

AHPM4, AHPT15 |

- |

|

Tool Bit |

W9 |

M42, M2Al |

HYCo10 |

- |

|

Press Mould |

M2 |

M35 |

AHPM4, APMT15 |

- |

here

for

price