- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

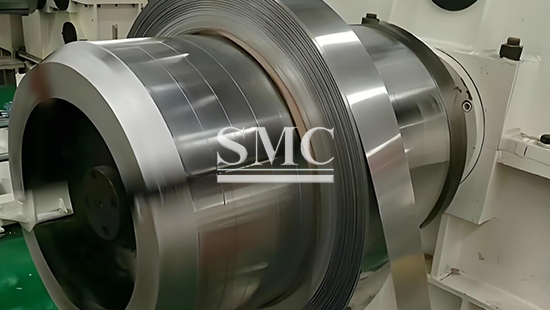

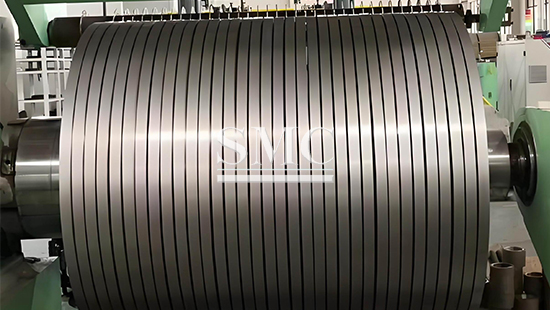

High Speed Steel Strip/ Tape

High-speed steel contains 0.6~1.3 % C and less S & P. It becomes alloy steel through adding W, Cr, Mo, Co, V and Mn. Among those elements, W, Mo and Co can improve strength of steel. The Cr enhance the oxidation resistance and wear resistance of steel. V improve the impact resistance, and Mn can improve the toughness of steel.

Shanghai Metal Corporation HSS is produced with electro-slag re-melting (ESR) or ladle furnace (LF) + vacuum degassing (VD) refine technology. With 30 years development, SMC has been forming a complete range of steel grade, the quality of HSS has reached an international level. Because of totally control chemical composition, size precision, alloy content, carbon saturation and purity, it makes it possible to offer a guarantee to customers in the reliability and identity of heat treatment performance and utilization property.

Shanghai metal Corporation is a professional manufacturer and supplier of high speed steel with high quality and reasonable price. If you want to know more about high speed steel products or high speed steel price please feel free to contact us, we will reply you within 24 hours.

-

Cold rolled HSS strip: Width 13-55mm thickness 0.60-1.80 mm

Hot rolled HSS strip: Width 16-65mm thickness 1.5-3.0mm

Steel Grade: M2, M35, M42, M51, etc.

Delivery status: annealed, quenched, tempered

Surface: black, grinding, polishing, bright, etc.

-

-

-

1. Gear Cutter

2. Hacksaw blade

3. Saw blades

4. Slitting saw

5. Circular saw blade

6. Cutting blade

7. Power planner replaceble blade

8. Sugar cane juice extractor blade

-

-

Technical Information of High Speed Steel Strip/Tape:

|

Steel Type |

Steel Grade |

||||||

|

GB9943 |

ISO 4957 |

JIS |

AISI |

ERASTEEL |

BOHLER |

||

|

HSS-E |

>4 5%Co |

W2MO9C「4VCO8 |

HS2-9-1-8 |

SKH59 |

M42 |

EM42 |

S500 |

|

W6Mo5Cr4V2Co5 |

HS6-5-2-5 |

SKH55 |

(M35) |

EM35 |

S705 |

||

|

VV7Mo4Cr4V2Co5 |

|

|

M41 |

|

|

||

|

W12Cr4V5Co5 |

HS12-1-5-5 |

SKH10 |

T15 |

|

|

||

|

W10Mo4Cr4V3Co10 |

HS10-4-3-10 |

SKH57 |

(T42) |

WKE42 |

S700 |

||

|

1%AI |

W6M05Cr4V2AI |

|

|

|

|

S620 |

|

|

>2.5%V |

W6Mo5Cr4V3 |

HS6-5-3 |

SKH53 |

M3-2 |

EM3 2 |

S607 |

|

|

CVV6Mo5Cr4V3 |

HS6-5-3C |

|

|

|

|

||

|

W6M05Cr4V4 |

HS6-5-4 |

SKH54 |

M4 |

|

|

||

|

HSS |

W6Mo5Cr4V2 |

HS6-5-2 |

SKH51 |

M2 |

|

|

|

|

VV6M05Cr4V2 |

HS6-5-2 |

SKH51 |

M2 |

|

|

||

|

CW6Mo5Cr4V2 |

HS6-5-2C |

|

CM2 |

EM2 |

S600 |

||

|

W6M06Cr4V2 |

HS6-6-2 |

|

|

|

|

||

|

(VV6Mo3Cr4V2) |

|

|

|

|

|

||

|

W9Mo3Cr4V |

|

|

|

|

|

||

|

VV2Mo8Cr4V |

HS1-8-1 |

|

M1 |

|

|

||

|

W2Mo9Cr4V2 |

HS2-9-2 |

SKH58 |

M7 |

EM7 |

S400 |

||

|

W18Cr4V |

HS18-0-1 |

SKH2 |

T1 |

ET1 |

S200 |

||

|

HSS-L |

W1 Mo4Cr4V2 |

HS1-4-2 |

|

M52 |

|

|

|

|

W4Mo3Cr4VSi |

|

|

|

|

|

||

|

W3M03C「4V2 |

HS3-3-2 |

|

|

ABCIII |

|

||

|

(W3Mo2Cr4V2Si) |

|

|

|

|

|

||

Chemical Component:

|

Grade |

Chemical Component |

||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

W |

V |

|

|

1.3343 |

0.86-0.94 |

≤0.45 |

≤0.40 |

≤0.030 |

≤0.030 |

3.80-4.50 |

4.70-5.20 |

5.90-6.70 |

1.70-2.10 |

|

M2 |

0.78-0.88 |

0.20-0.45 |

0.15-0.40 |

≤0.030 |

≤0.030 |

3.75-4.50 |

4.50-5.50 |

5.50-6.75 |

1.75-2.20 |

|

W6Mo5Cr4V2 |

0.80-0.90 |

0.20-0.45 |

0.15-0.40 |

≤0.030 |

≤0.030 |

3.80-4.40 |

4.50-5.50 |

5.50-6.75 |

1.75-2.20 |

Physical Property:

|

Temperature °C |

Density g/cm3 |

Modulus of elasticity |

Coefficient of thermal expansion |

Heat transfer coefficient |

Specific heat |

|

KN/mm2 |

W/m°C |

J/kg°C |

|||

|

20 |

8.16 |

225 |

/ |

24 |

420 |

|

400 |

8.06 |

200 |

1.21×10-6 |

28 |

510 |

|

600 |

8 |

180 |

1.26×10-6 |

27 |

600 |

Packaging of High Speed Steel Strip/Tape/Sheet:

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

here

for

price