- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Inconel 617

Model Number: Inconel 617

Shape: Forging & Cold Drawn

Standard: ASTM ASME

Shanghai Metal Corporation is a professional manufacturer and supplier of Inconel 617 products with high quality and reasonable price.

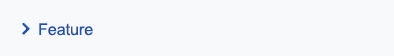

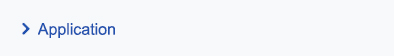

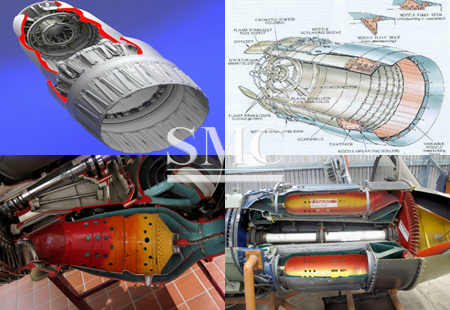

Inconel617 alloy has excellent corrosion resistance and creep performance in the field of hot corrosion, especially in sulfurization environments, especially in oxidation and carbonization environments with cycles up to 1100 ℃. These corrosion resistance combined with excellent mechanical properties make this alloy particularly suitable for high-temperature applications. Has good short-term and long-term mechanical properties at high temperatures up to 1100 ℃. Excellent anti carburizing performance and good weldability at high temperatures up to 1100 ℃.

If you want to know more about price of Inconel 617 products, please feel free to contact us, we will reply you within 24 hours.

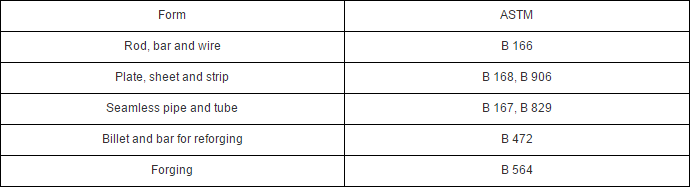

1. ASTM Standard Of Products

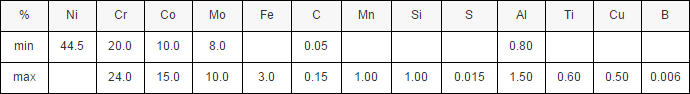

2. Chemical composition

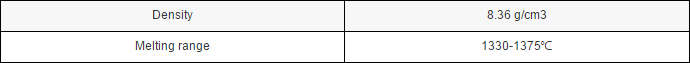

3. Physical properties

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation.

In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)Shanghai Metal Standard

2)Customization

1. Hot and Cold Forming

Alloy 617 has good hot formability, but it requires relatively high forces because of its inherent strength at elevated temperatures. In general, the hot-forming characteristics of alloy 617 are similar to those of INCONEL alloy 625. The temperature range for heavy forming or forging is 1850 to 2200°F (1010 to 1205°C). Light working can be done at temperatures down to 1700°F (925°C). INCONEL alloy 617 is readily cold formed by conventional procedures although its work-hardening rate. For best results, the alloy should be cold formed in the fine-grain condition, and frequent intermediate anneals should be used. Annealing for cold forming should be done at 1900°F (1040°C).

2. Heat Treatment

INCONEL alloy 617 is normally used in the solutionannealed condition. That condition provides a coarse grain structure for the best creep-rupture strength. It also provides the best bend ductility at room temperature. Solution annealing is performed at a temperature of 2150°F (1175°C) for a time commensurate with section size. Cooling should be by water quenching or rapid air cooling.

3. Machining

Cutting tools should be sharp and have positive rake angles to minimize work hardening of the material. Cutting feed and depth of cut must be sufficient to prevent burnishing of the workpiece surface.

4. Joining

INCONEL alloy 617 has excellent weldability. INCONEL Filler Metal 617 is used for gas-tungsten-arc and gas-metalarc welding while INCONEL Welding Electrode 117 is used for shielded metal-arc welding. The composition of the filler metal matches that of the base metal, and deposited weld metal is comparable to the wrought alloy in strength and corrosion resistance.

here

for

price