- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

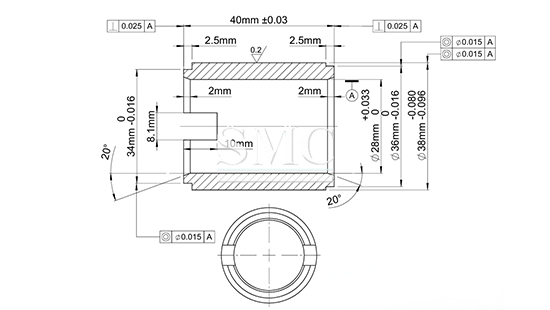

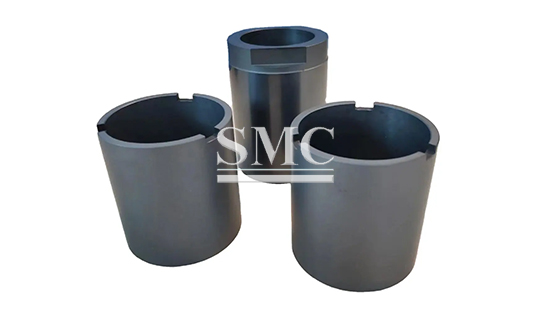

Silicon Carbide Bushing/ Sleeve

Material: Silicon Carbide (SiC)

Density(g/cm³): >3.10

Hardness(Kg/mm2): 2800

Fracture toughness (MPa·m⁻³/²): 4-5

Shanghai Metal Corporation is a leading Silicon Carbide Bushing manufacturer and supplier.

Silicon carbide bushing showcases exceptional properties. It has an extremely high hardness, often over 2000 HV, ensuring outstanding wear resistance against abrasive substances. Its corrosion resistance is remarkable, resisting a wide array of aggressive chemicals. Capable of withstanding high temperatures up to around 1600 °C, it maintains structural integrity and performance. This bushing is designed to operate in the harshest environments and special conditions, finding applications in aircraft engine components in aviation, high - performance spacecraft systems in aerospace, downhole tools and pumps in the oil and gas sector, linings in industrial pumps, and high - precision semiconductor manufacturing equipment. As a prime example of advanced material application, it represents a technological leap in high - tech manufacturing, enabling more reliable and efficient equipment across diverse industries.

If you want to know more about our Silicon Carbide Bushing price please feel free to contact us, we will reply you within 24 hours.

Technical Information of Silicon Carbide Bushing/Sleeve:

|

Technical Parameters |

|||||

|

Attribute |

unit |

Material |

|||

|

Type |

|

SiC |

SiSiC |

NSiC |

|

|

Chemical Composition - SiC % |

SiC % |

89 |

87 |

92 |

70 |

|

|

SiO₂ % |

5 |

6 |

- |

Si3N4 28 |

|

|

Al₂O₃ % |

1.0 |

2.0 |

- |

- |

|

Bulk Density |

(g/cm³) |

2.85 |

2.8 |

3.01 |

2.8 |

|

Apparent Porosity |

(%) |

12 |

14 |

0.1 |

12 |

|

M.O.R.@ 20 ℃ |

(MPa) |

50 |

48 |

260 |

180 |

|

M.O.R.@ 1300 ℃ |

(MPa) |

58 |

56 |

280 |

185 |

|

C.T.E.@ 20 ℃ - 1000 ℃ |

(10⁻⁶K⁻¹) |

4.8 |

4.2 |

4.5 |

4.7 |

|

C.C.S |

(MPa) |

100 |

90 |

900 |

500 |

|

Thermal Shock Resistance |

1 |

5 |

5 |

5 |

5 |

|

Maximum Operating Temperature |

(℃) |

1450 |

1420 |

1300 |

1500 |

|

Applications |

Used in ceramic shuttle kilns, tunnel kilns, roller hearth kilns, and kiln furniture |

||||

here

for

price