- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

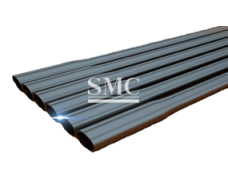

Thermal Lance

Function: heat and melt steel in the presence of pressurized oxygen

A Thermal Lance, thermic lance, oxygen lance, or burning bar is a tool that heats and melts steel in the presence of pressurized oxygen to create the very high temperatures (≥3600°C) required for cutting. It consists of a long steel tube packed with alloy steel rods, sometimes mixed with aluminium rods to increase the heat output. One end of the tube is placed in a holder and oxygen is fed through the tube.

The far end of the tube is pre-heated and lit by an oxyacetylene torch. An intense stream of burning steel is produced at the workpiece end and can be used to cut rapidly through thick materials including steel and concrete.The tube is consumed, so every few minutes the oper ator shuts off the oxygen, discards the remaining stub of a lance tube and starts using a new one.

Although often used as a heavy duty demolition tool, the thermic lance can also be used to remove seized axles of heavy machinery without damaging the bearings or axle housing. This technique is most often used on the pins and axles of large equipment such as cranes,ships, bridges and sluice-gates.

It is used in steel-making for boring of concrete structure,remove burned sand,cutting stainless steel and nonferrous metal.cutting riser in ductile cast iron,cutting sheet or pipe pile and some other special steel,cutting pig iron mixed with slag,cutting blast furnace shell,cutting& boring furnace bottom refractory brick.

Technical Information of thermal lance:

|

N o m i n a l S i z e |

O D ( m m ) |

WT(mm) |

L(M) |

Bundle |

|

6A(1/8") |

10 |

1 |

1.8 /3 / 5 |

500 |

|

8 A(1/4") |

13.7 |

1.5 |

1. 8 /3 /5 |

400 |

|

10 A(3/8") |

17.1 |

2 |

1.8 /3 /5 |

300 |

|

1SA(1/2") |

21.3 |

2 |

2.75/3.2/5 |

200 |

|

20 A(3/4") |

26.7 |

2.5 |

2.75 /3. 2/5 |

100 |

Packaging of Thermal Lance:

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

More of thermal lance:

Burn open large, bottom pouring smelting furnaces

Remove carbon during the smelting process of various metals

Lower oxygen and lance consumptions

Full length burning, thanks to its exclusive coupling system

Focused on the attack point resulting in more accurate cuts

Faster operations decreased operator’s exposure time

Less fumes and sparks are generated, easier to operate

here

for

price