- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

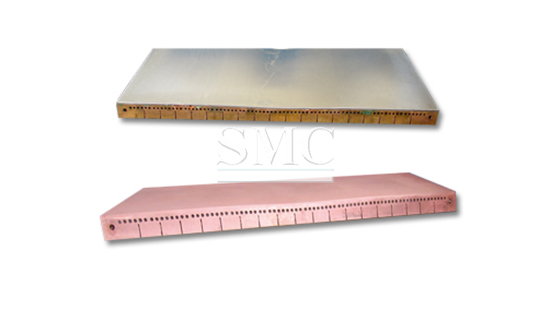

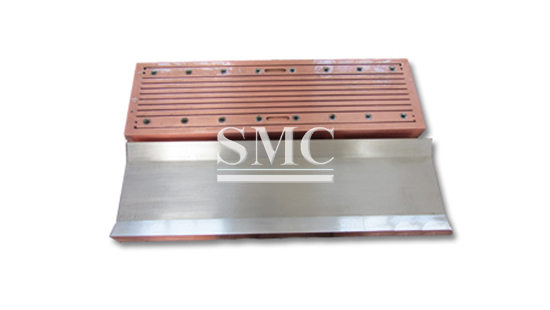

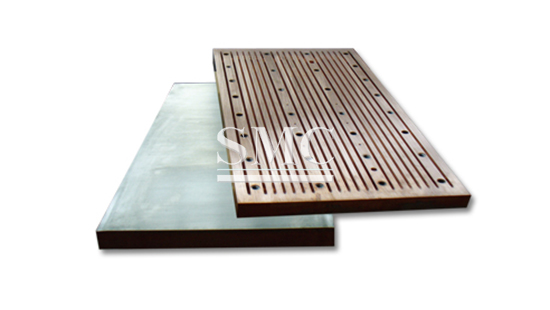

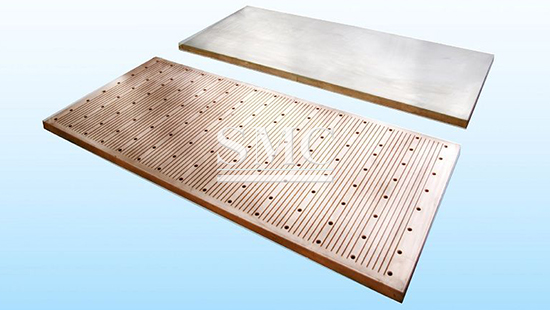

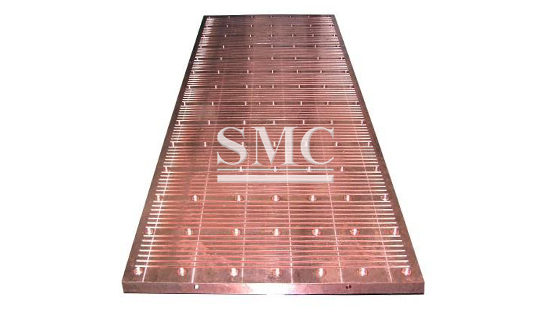

Crystallizer Copper Plate

Thickness: 40~60mm

Length: 180~1000mm

Metarial: Copper, Brass

The crystallizer is the core of the continuous casting machine. Its function is to force the molten steel that is continuously injected into its inner cavity through the water-cooled copper plate to force the heat of the molten steel, so that it gradually solidifies to have the required cross-sectional shape and certain uniformity. The thickness of the billet shell and the casting of the billet with the liquid phase in the core are continuously pulled out from the lower mouth of the crystallizer to create conditions for its complete solidification in the secondary cooling area. The solidification of molten steel in the mold has a significant impact on the surface quality of the casting yard and the normal production of the casting machine.In the solidification process of high-temperature molten steel injected into the mold and gradually forming a billet of a certain thickness, the copper plate of the mold has been in the molten steel and cooling water. Static pressure, high temperature oxidation, thermal cracks caused by hot and cold fatigue, large temperature gradients, deformation, chemical corrosion of cooling water and protective slag components, high temperature steam erosion, friction, wear and cone adjustment caused by ingots, billets, vibration Many scratches such as scratches caused by width.

-

One is brass and other vertical semi-continuous casting crystallizer, the material is mainly copper, the structure is in the form of a closed ring, the inner cavity is slightly larger than the shape of the casting material, the inner surface is electroplated, the outermost is outside the steel lining plate, and the rest are all Red copper, thickness about 60mm, length about 180~220mm.

One is in the form of copper plate, the material includes the above-mentioned various brands, the thickness specification is generally about 40mm or less, the length is about 700~1000mm, and the width is determined according to the width of the casting material.

-

-

-

(1) Good thermal conductivity

(2) Higher high-temperature strength.

(3) Good high temperature wear resistance.

(4) Good process performance.

(5) Better performance-price ratio

here

for

price