- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

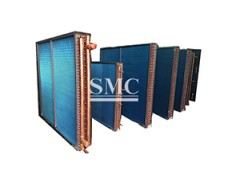

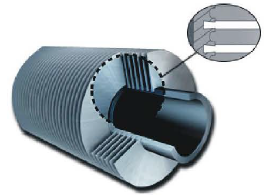

Spiral Fin Tube

Tube Material: Carbon Steel, Stainless Steel, Copper, Aluminum, Cupro Nickel, etc.

Fin Material: Aluminum, Copper, Steel, etc.

Tube Size: Customized

Fin Size: Customized.

Shanghai Metal Corporation is a leading Spiral Fin Tube manufacturer and supplier.

Spiral finned tubes are a type of pipe used to increase the heat exchange surface area and are often employed in heat exchangers and air coolers. These pipes are usually composed of an inner tube (typically a heat conductor) and external spiral fins. The specifications of spiral finned tubes can vary depending on the manufacturer and specific application.

If you want to know more about our Spiral Fin Tube price or other heat exchanger products price please feel free to contact us, we will reply you within 24 hours.

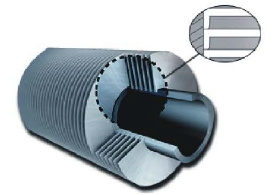

Classification of spiral finned tube fins

L Fin

L shaped strip gives optimum contact pressure of the fin foot onto the base tube, thus improving the heat transfer efficiency. This also gives considerable corrosion protection to the base tube.

Max. working temperature: 270 ℃

Fin Materials: Aluminum, copper

LL Fin

LL fin same as L fin, except the fin foot is overlapped giving more corrosion protection. This type of finned tube is often used as an alternative to the more expensive extruded type fin in corrosive environments.

Max. working temperature: 165 ℃

Fin Materials: Aluminum, copper

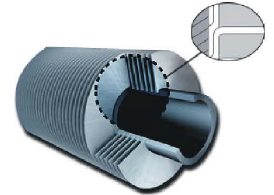

KL Fin

KL fin same as L fin, same as L fin except that the base tube is knurled before application of the fin foot. After application, the fin foot is knurled into the corresponding knurling on the base tube, thereby enhancing the bond between the fin and tube, resulting in improved heat transfer characteristics.

Max. working temperature: 260 ℃

Fin Materials: Aluminum, copper

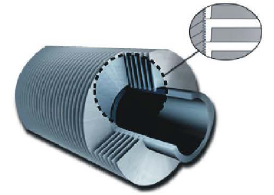

G Fin

G fin strip is wound into a machined groove on the tube surface and securely locked into place by back filling with base tube material. This offers exceptional heat transfer efficiency at higher tube metal temperature.

Max. working temperature: 400 ℃

Fin Materials: Aluminum, copper, carbon steel, etc.

Packaging of Spiral Fin Tube

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. Foam Paper carton, Pearl cotton carton, Wooden Pallet is adpoted. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

.jpg)

.jpg)

Common size of Spiral Fin Tube

| No | Fin Material | Base tube mm |

Fin mm |

Fin Pitch mm |

| 1 | Aluminum | 15.88 | 38.1 | 2.74 |

| 2 | Aluminum | 19.05 | 44.45 | 2.31 |

| 3 | Aluminum | 22 | 42 | 2.5 |

| 4 | Aluminum | 25 | 45 | 3.2 |

| 5 | Aluminum | 25 | 53 | 2.5 |

| 6 | Aluminum | 25 | 55 | 2.3 |

| 7 | Aluminum | 25 | 57 | 2.5 |

| 8 | Aluminum | 25.4 | 57.15 | 2.34 |

| 9 | Aluminum | 27 | 72 | 12 |

| 10 | Aluminum | 32 | 77 | 12 |

| 11 | Aluminum | 33.7 | 66 | 2.5 |

| 12 | Steel | 18 | 38 | 3 |

| 13 | Steel | 19 | 41 | 3 |

| 14 | Steel | 19 | 46 | 4 |

| 15 | Steel | 21 | 40 | 3.6 |

| 16 | Steel | 25 | 50 | 2.5 |

| 17 | Steel | 25 | 57 | 6 |

| 18 | Steel | 32 | 72 | 8 |

|

||||

Other size can be customized as per customers request.

Advantages of Spiral Fin Tube

1. Enhanced Heat Transfer:

Increased Surface Area: The spiral shape of the fins significantly increases the surface area available for heat exchange, allowing for more efficient transfer of heat between the fluid inside the tube and the surrounding environment.

Turbulent Flow: The spiral configuration disrupts the fluid flow, creating turbulence. This turbulence promotes better mixing of the fluid, further enhancing heat transfer. Uniform Heat Distribution: The helical arrangement of the fins helps distribute heat more evenly across the tube, preventing localized hot spots and improving overall heat transfer efficiency.

2. Compact Design:

Space Efficiency: Spiral fin tubes can achieve a higher heat transfer rate within a smaller footprint compared to other finned tube designs, making them suitable for applications where space is limited.

3. Reduced Fouling:

Self-Cleaning Effect: The continuous spiral design of the fins can help reduce fouling (the build-up of deposits on the surface) by minimizing crevices where debris can accumulate.

4. Durability and Cost:

Resistance to Corrosion: Depending on the materials used, spiral fin tubes can be designed to be highly resistant to corrosion, ensuring a longer service life.

Potential for Cost Savings: While the manufacturing process can be more complex, the enhanced heat transfer and reduced fouling can lead to long-term cost savings through increased efficiency and reduced maintenance.

5. Versatility:

Wide Range of Applications: Spiral fin tubes find applications in various industries, including HVAC, petrochemical, power generation, and waste heat recovery.

Material Flexibility: They can be manufactured using a variety of materials, including stainless steel, aluminum, and copper, to suit different operating conditions and requirements.

Its important to note that while embedded spiral fin tubes offer significant heat transfer advantages, their design and installation may require specialized knowledge and equipment. When considering the use of embedded spiral fin tubes in a specific application, its advisable to consult with experts or engineers to ensure proper selection, design, and installation for optimal performance.

here

for

price

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)