- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Enameled Aluminum Wire

Wire diameter: 0.2mm - 6.5mm

Heat shock: 120℃ - 300℃

MOQ: 100kg - 500kg

Shanghai Metal Corporation is a leading Enameled Aluminum Wire and supplier.

Shanghai Metal Corporation capacity of round enamelled aluminum wire is 35,000tons. The main products are:240 class composite enamelled aluminum wire, 220 class composite enamelled aluminum wire, 200 class polyesterimide enamelled aluminum wire, 130-180 class polyester and polyurethane enamelled aluminum wire, and we can also produce various types of enamelled round aluminum wire according to the customer's requirements.

Shanghai Metal Corporation is a professional manufacturer and supplier of Aluminum Wire For Alloy Wire Material,Enameled Aluminum Wire, We also supply Aluminum Flat Wire, Aluminum Magnesium Alloy Wire (Al-Mg Alloy Wire).

If you want to know more about our Aluminum products or Enameled Aluminum Wire price please feel free to contact us, we will reply you within 24 hours.

Features of Round Enameled Aluminum Wire:

1) Excellent bending property

2) High flexibility of the enamel

3) Good resistance to abrasion

4) High mechanical property

5) Higher thermal property

6) Good resistance to refrigerant and freon

7) Suitable for windings that are subjected to constantly high temperature and mechanical stress

8) Good chemical resistance

9) Outstanding mechanical and chemical property

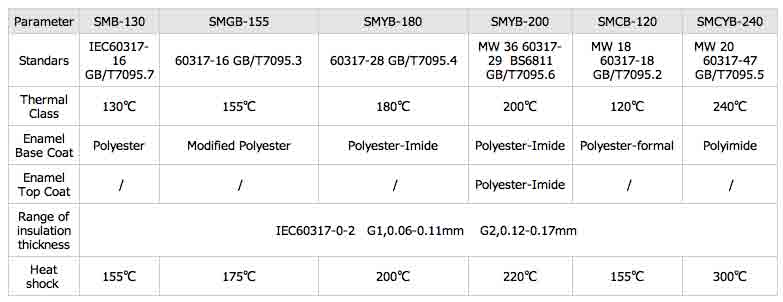

Parameters of Round Enameled Aluminum Wire:

Packaging of Round Enameled Aluminum Wire

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Round Enameled Aluminum Wire:

a) Small transformers, linear motors, relays, solenoids, small motors,

clock coils, watch coils, magnetic heads

b) Automotive sensors and coils as relais and ignition coils

c) Generators, dry-type or oil-immersed

d) Anti-explosion motor, air-conditioner compressor, washing machine

e) Military and space applications

Aluminum enameled wire welding

For welding of aluminum enameled wire, the welded workpiece should be well formed, reliable and easy to operate.

A common method for welding aluminum enameled wire is to use a special flux-cored wire to solder with an electric iron. Generally, the welding of aluminum enameled wire and aluminum enameled wire / bare aluminum wire / aluminum alloy / copper wire with a smaller diameter is suitable for this type of welding Method (flame brazing can be used for wires, bars and foils with large diameters or large areas). The workpieces welded by this welding method should be well formed, reliable and easy to operate.

Welding instructions: When soldering, the soldering iron head should be as close as possible to the object to be welded, and then the solder wire should be sent to the soldering iron head to melt the solder wire and complete the welding (this method allows the flux in the solder wire to fully contact the board surface to achieve the best Welding effect); For welding of enameled aluminum wire and copper wire (or aluminum wire), the two wires are usually connected by twisting the twisted wire after scraping the paint, and the size of the twisted twist directly affects the welding effect. The larger the amount of tin is, the stronger the welding between the two wires is. For freshly welded enameled wire, don't pull it too fast, and wait for it to completely cool before checking its reliability. For the unused solder wire, use a lighter to burn the wire head into a ball shape, so as to avoid the loss of liquid flux in the wire, which will affect the next welding.

here

for

price