- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

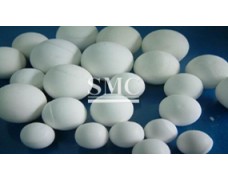

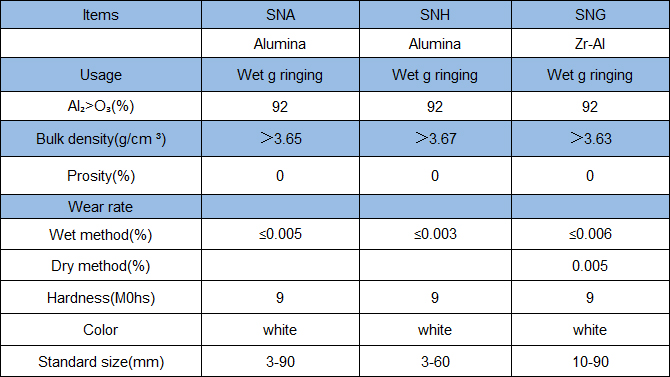

Corundum Grinding Ball/ Alumina Ball

Diameter: 0.5mm-30mm

Material: Alumina

Shanghai Metal Corporation is a leading corundum grinding ball/alumina ball manufacturer and supplier.

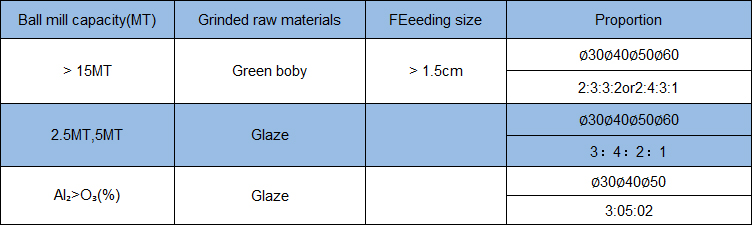

The main component of corundum grinding ball/alumina ball is high-quality alumina, with high purity, high strength, high hardness, high whiteness, low abrasion, and basically no effect on the quality of the grinding material. The product adopts rolling and isostatic pressing, with a large specific gravity which can greatly improve the grinding efficiency, reduce the grinding time, and increase the effective capacity of the ball mill, thereby increasing the amount of grinding material added. It has low abrasion and can greatly extend the service life of the grinding body. It has a high mechanical strength, a long life cycle, good chemical stability, no chemical reactions with the material, high temperature resistance, etc. (Maximum heat resistance up to 1200 ℃)

If you want to know more about our aluminum electrical wire/wiring, aluminum sheets, aluminum wire, please feel free to contact us. We will reply to you within 24 hours.

Plastic Bag; Jumbo Bag; Steel drum packing for ceramic balls

Applications:

A. Mainly used in different types of ceramic, enamel, glass, thick hard material of chemical plant finishing and deep processing. It is a grinding medium for fine-grinding equipment such as ball mills, jar mills and vibratory mills. Wear resistance is much better than ordinary ball stone or natural pebbles.

B. Non-metallic mineral powders (such as zirconium silicate, kaolin, heavy calcium carbonate, etc.) and coatings, paints and other industries grinding and dispersing materials and the use of metal polishing, suitable for all types of grinding and polishing equipment.

C. Filling in the rubber when pouring can increase the wear coefficient

D. High temperature resistant, can be used as the ball which under the pushed slab kiln

E. High strength, high hardness can be used for polishing

here

for

price