- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Tinsel Wire

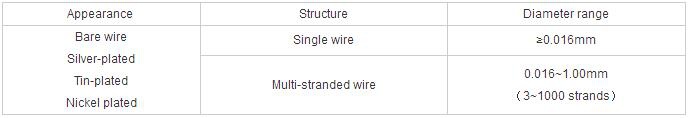

Diameter:

Single wire ≥0.016mm,

Multi-stranded wire 0.016~1.00mm(3~1000 strands)

Shanghai Metal Corporation is a leading Tinsel Wire manufacturer and supplier.

Tinsel wire is a type of electrical wire used for applications that require high mechanical flexibility but low current-carrying capacity. Copper tinsel wires are made of copper foil ribbon conductor round wire after flattening, helically wound on the fiber, to the fiber to form a circular support centered on the package assembly.

According to the different kinds of copper conductors, generally can be divided into: bare copper tinsel wire, tin-plated copper tinsel wire, silver-plated copper tinsel wire, bare copper alloy tinsel wire, tin-plated copper alloy tinsel wire, silver plated copper alloy tinsel wire etc., ;Depending on the center of the fiber material, generally it can be divided into: polyester copper tinsel wire, aramid fiber copper tinsel wire, poly aromatic ester fiber copper tinsel wire; The number of strip foil wrapped, copper tinsel wire wrapped into a single layer, double-wrapped copper tinsel wire, three-wrapped copper tinsel wire and so on; The post-processing step of copper tinsel wire, copper tinsel wire into copper tinsel stranded wire, copper tinsel braided wire.

If you want to know more about our Tinsel Wire or other copper wire price please feel free to contact us, we will reply you within 24 hours.

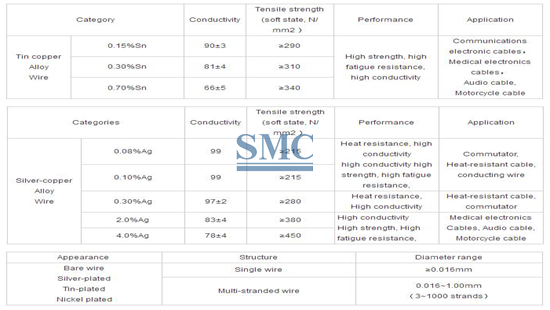

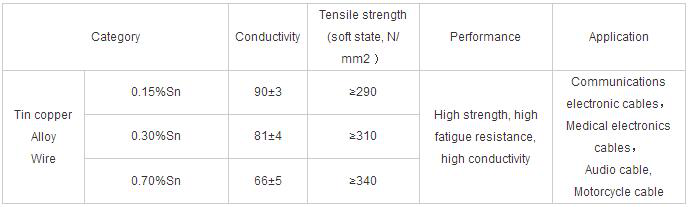

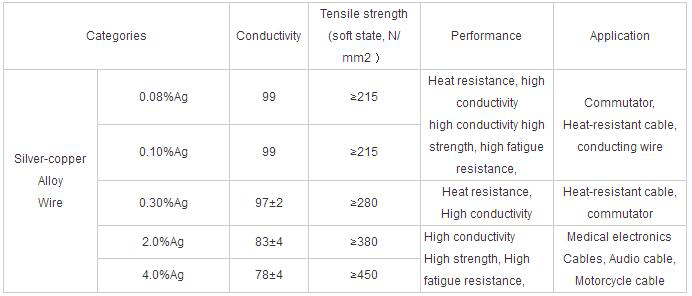

Technical information of tinsel wires:

1)Category of copper tinsel wires:

1. According to the different kinds of copper conductors, generally can be divided into: bare copper tinsel wire, tin-plated copper tinsel wire, silver-plated copper tinsel wire, bare copper alloy tinsel wire, tin-plated copper alloy tinsel wire, silver plated copper alloy tinsel wire etc., ;

2. Depending on the center of the fiber material, generally it can be divided into: polyester copper tinsel wire, aramid fiber copper tinsel wire, poly aromatic ester fiber copper tinsel wire;

3. The number of strip foil wrapped, copper tinsel wire wrapped into a single layer, double-wrapped copper tinsel wire, three-wrapped copper tinsel wire and so on;

4. The post-processing step of copper tinsel wire, copper tinsel wire into copper tinsel stranded wire, copper tinsel braided wire.

2)Processing method of tinsel wires:

Raw materials→reduction→metal powder→mixing→pressing→firing→ forming→heat treatment→processing connection plating→finished products

Packaging of Rhenium Sheet

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Application of Tinsel Wire:

Tinsel wire is commonly used in cords of telephones, handsets, headphones, and small electrical appliances. It is far more resistant to metal fatigue failure than either stranded wire or solid wire.

Advantage and limitation of Tinsel Wire:

1. The foil strip helically wound on the central fiber, fiber will play a key role withstand longitudinal tension; and because retain a certain gap between the copper foil wrapping, so that the strip-shaped copper tinsel wire when subjected to bending. It can be avoided by a large deformation, so that the copper tinsel wires have good flexibility, softness and resistance to bending properties, particularly resistance to bending performance is much higher than conventional round wire conductors. If the selection of copper alloy foil wire, its performance will have a greater resistance to bending higher than copper tinsel wire.

2. As it is helically wound around the package assembly, single wire diameter increases, the increase per meter resistance value of products using the occasion to be based on the fiber temperature levels, depending on the above factors make the selection of copper wires certain extents limits.

3. By using a copper alloy as a conductor, can be further increased resistance to bending performance copper tinsel wires, but the resistance value per meter will further increase.

4. By increasing the copper tinsel wires of the surface treatment process, can significantly improve the oxidation resistance of products to meet high level customers for the product salt spray test requirements.

here

for

price