- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

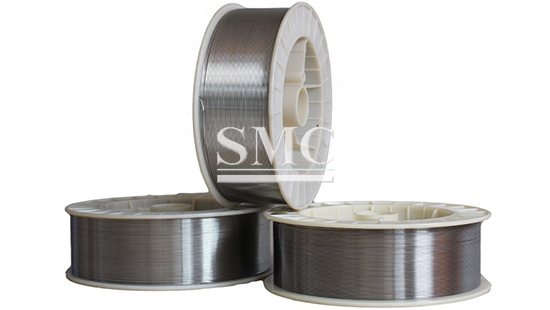

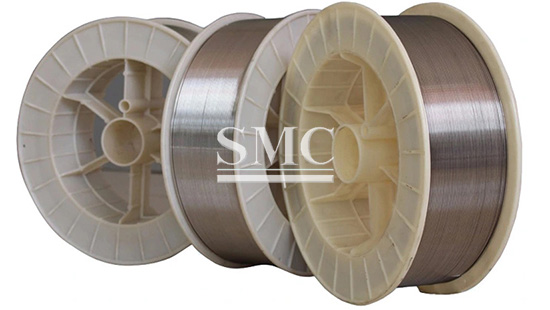

Hardfacing Welding Wire

Alloy: HS101、HS103、HS111、YD212-1、YD247-1、HYD047、HYD057etc.

Hardness of hardfacing layer HRC: 48-60

Shanghai Metal Corporation is a leading Hardfacing welding wire supplier and manufacturer.

Wear resistant welding wire is a kind of welding wire which can resist more than two types of composite wear. According to its chemical composition, it can be divided into two categories: iron-based hardfacing welding wire and non-ferrous base surfacing wear-resistant welding wire. According to the structure of welding wire, it can be divided into solid core welding wire and flux core (also known as tubular) welding wire. According to the welding process, it can be divided into gas shielded welding, submerged arc welding, flame surfacing, plasma surfacing and spray welding.

If you want to know more about our Hardfacing welding wire price please feel free to contact us, we will reply you within 24 hours.

-

1.Diameter: 1.2-3.2 mm

2. Flux content: 20%

3. Type: solid core

-

-

-

1.Cost saving.

2.Improve the service life of the workpiece.

3.Good abrasive wear resistance

4. Impact wear resistance

5. Adhesive wear resistance (metal to metal wear)

6. High temperature wear resistance

-

1. It is used for surfacing welding parts with wear resistance, oxidation resistance or cavitation resistance.

2. It is used for surfacing welding of underwater machinery damaged by sand abrasion and cavitation

3. Tungsten carbide flux cored wire, used in mining equipment, etc

-

here

for

price